12 Tips to Reduce Machining Vibrations during CNC Milling

What is machining vibration?

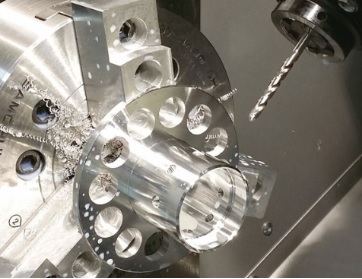

Machining vibrations, also called chatter, correspond to the relative movement between the workpiece and the cutting tool. The vibrations result in waves on the machined surface. This affects typical machining processes, such as turning,

milling and drilling, and atypical machining processes, such as grinding. A chatter mark is an irregular surface flaw left by a wheel that is out of true in grinding or regular mark left when turning a long piece on a lathe, due to machining vibrations.

As early as 1907, Frederick W. Taylor described machining vibrations as the most obscure and delicate of all the problems facing the machinist, an observation still true today, as shown in many publications on machining. Mathematical models make it possible to simulate machining vibration quite accurately, but in practice, it is always difficult to avoid vibrations. This article is going to offer some tips to reduce machining vibration during CNC milling.

Tips to reduce machining vibrations during CNC milling

1. Use sharp blades to reduce the cutting force of the CNC milling machine. Machine clamp blades are divided into coated and non-coated blades. Non-coated blades are usually sharper than coated blades, because if the blade is to be coated, the cutting edge must be passivated (ER treatment), because the sharp The cutting edge will affect the bonding strength of the coating at the cutting edge.

2. When the cutting depth is constant, the use of a small tooltip arc radius can undoubtedly reduce the cutting force. Especially the radial cutting force, and the radial cutting force is the main cause of the vibration of the elongated rod tool or workpiece. Whether it is ramming or milling. At the same cutting depth, the radius of the tool nose arc is larger. The slender tool shaft has a greater tendency to vibrate.

3. When the cutting depth can be selected, avoid the cutting depth equal to the radius of the tooltip arc.

4. For key cutting with a sharp knife with a slender toolbar, or external turning of a slender shaft, the use of a tool with an entering angle of 90°is beneficial to damping vibration. Whether it is turning a slender shaft with an external turning tool, or a key tool hole of a slender tool bar, it is always 90°, and the tool with an entering angle produces the smallest radial cutting force. At the same time, the axial force generated by the blade edge is the largest.

5. For milling cutters with slender rods, round blade milling cutters are most conducive to damping vibration. The milling cutter is opposite to the stirring cutter. The closer the entering angle is to 90°, the greater the radial cutting force, and the greater the vibration of the cutter bar. Therefore, in the face milling of the deep hole cavity of the mold, the CNC milling machine usually uses a 45°entering angle milling cutter, if the depth of cut is less than 1mm. Often use round blade milling cutter or ball cutter.

6. When the CNC milling machine uses a slender rod end mill to mill a deep cavity, plunge milling is often used. Plunge milling is the axial feed of the tool like a drill bit. When milling deep cavities. Usually, the overhang of the long rod is greater than 3 times the diameter of the tool shank. We recommend using the plunge milling method of axial feed. However, the edge of the end mill insert has a radial cutting edge with a certain width. The tool supplier has technical data to prove the maximum cutting width of the tool during plunge milling.

7. The cause of vibration in the milling of thin-walled workpieces is entirely from the workpiece, which is called box or bowl parts. Since the vibration comes from the workpiece itself, when processing this type of part milling, the main focus is to improve the clamping of the workpiece.

8. When boring the inner hole, the smaller the blade edge angle, the better. In this way, the secondary main deflection angle is large, and the vibration contact area between the secondary cutting edge and the machined surface is small, and the vibration is difficult to turn into vibration. The secondary cutting edge has a small chance of chip extrusion.

9. If the face milling cutter adopts sparse tooth unequal distance milling cutter, milling vibration can be reduced. Here "tooth" refers to the blade. Face milling cutter of the same diameter (for example 100mm). If their three cutting elements are equal, then the cutter head with 5 blades must produce 50% less milling force than the cutter head with 10 blades.

10. Use blades with a positive rake angle and a large back angle. And with a brisk chip breaker. Such blades have the smallest cutting wedge angle in filing or milling, and the cutting is of course brisk.

11. Adjust cutting parameters. Adjusting the cutting parameters may be effective only when the cutting vibration is not serious. The general adjustment method is as follows: reduce the rotation speed of the tool or workpiece, reduce the depth of cut and increase the amount of cutting per revolution or the milling cutter. If vibration occurs during the turning of the internal thread, the feed steps to complete the thread turning can be reduced by one to two.

12. Reasonably arrange the process path of the knife. Arranging the process path of the tool reasonably is very important for milling processing. Milling is divided into down milling and up milling. According to the traditional milling theory, the use of up-milling is beneficial to reduce milling vibration, but it actually means that it is beneficial to suppress the vibration generated by the screw gap. Today's milling equipment is mostly equipped with ball or roller screws. Therefore, up-milling is of little significance. Whether it is down milling or up milling. As long as the direction of the milling force is consistent with the clamping direction of the workpiece, it will help eliminate the vibration of the bent plate parts.