5 Kinds of Advanced Deburring Processes

Burrs are everywhere in the metal processing process. No matter how advanced precision equipment you use, it will be born with the product. It is mainly a kind of extra iron filings generated at the processing edge of the processed material due to the plastic deformation of the material, especially the material with good ductility or toughness, which is particularly prone to burrs.

The main types of burrs include flash burrs, sharp corner burrs, splashes, etc., a prominent excess metal remnant that does not meet product design requirements. For this problem, so far there is no effective way to eliminate it in the production process. Therefore, in order to ensure the design requirements of the product, engineers have to work hard on the removal of the latter. So far, different products are different. There are many methods and equipment for removing burrs.

4 levels of deburring

In general, the methods for removing burrs can be divided into four categories:

1. Coarse (hard contact)

This category includes cutting, grinding, filing and scraper processing.

2. Normal grade (soft touch)

Belonging to this category are belt grinding, grinding, elastic wheel grinding and polishing.

3. Precision level (flexible contact)

In this category, there are washing processing, electrochemical processing, electrolytic grinding and rolling processing.

4. Ultra-precision level (precision contact)

In this category, there are abrasive flow deburring, magnetic abrasive deburring, electrolytic deburring, thermal energy deburring, and strong ultrasonic deburring with dense radium. These deburring methods can obtain sufficient parts processing accuracy.

1. Electrolytic deburring

When we choose the deburring method, we must consider many factors, such as the material characteristics, structural shape, size and precision of the part, especially the surface roughness, dimensional tolerance, deformation, and residual stress.

The so-called electrolytic deburring is a chemical deburring method, which can remove the burrs after machining, grinding and stamping, and round or chamfer the sharp edges of metal parts.

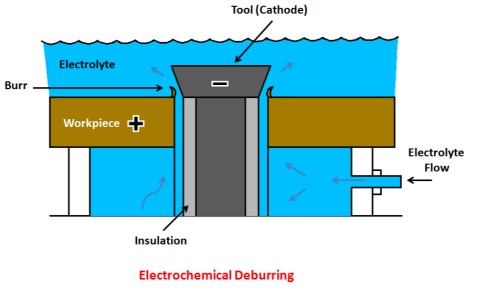

An electrolytic machining method that uses electrolysis to remove burrs on metal parts, referred to as ECD in English. Fix the tool cathode (usually brass) near the burr part of the workpiece, with a certain gap between the two (usually 0.3 to 1 mm). The conductive part of the cathode of the tool is aligned with the edge of the burr, and the other surface is covered with an insulating layer to concentrate the electrolysis on the burr.

During processing, the tool cathode is connected to the negative pole of the DC power supply, and the workpiece is connected to the positive pole of the DC power supply. A low-pressure electrolyte with a pressure of 0.1 to 0.3 MPa (usually sodium nitrate or sodium chlorate aqueous solution) flows between the workpiece and the cathode. When the DC power supply is turned on, the burrs will be dissolved and removed by the anode, and will be taken away by the electrolyte.

The electrolyte is corrosive to a certain extent, and the workpiece should be cleaned and anti-rust treated after deburring. Electrolytic deburring is suitable for removing burrs from cross holes in hidden parts or parts with complex shapes. The production efficiency is high. The deburring time generally only takes a few seconds to tens of seconds.

This method is often used for deburring gears, splines, connecting rods, valve bodies and crankshaft oil passages, as well as rounding sharp corners. The disadvantage is that the vicinity of the part burr is also subjected to electrolysis, the surface will lose its original luster, and even affect the dimensional accuracy.

Of course, in addition to electrolytic deburring, there are the following special deburring methods:

2. Deburring by abrasive flow

Abrasive flow machining technology (AFM) is a new finishing and deburring process developed in the late 1970s abroad. This process is particularly suitable for burrs that have just entered the finishing stage, but for small and long holes and metal molds with impassable bottoms. Not suitable for processing.

3. Magnetic grinding and deburring

This method originated in Eastern European countries such as the former Soviet Union and Bulgaria in the 1960s. In the mid-1980s, Japanese cars conducted in-depth research on its mechanism and application.

During magnetic grinding, the workpiece is placed in the magnetic field formed by the two magnetic poles, and magnetic abrasives are placed in the gap between the workpiece and the magnetic poles. The abrasives are arranged neatly along the direction of the magnetic field under the action of the magnetic field force, forming a soft and rigid magnetic grinding When the workpiece is vibrated axially in the rotating shaft in the magnetic field, the workpiece and the abrasive will move relative to each other, and the abrasive brush will grind the surface of the workpiece. The magnetic grinding method can efficiently and quickly grind and deburr the parts, and is suitable for Parts of various materials, sizes and structures are a finishing method with low investment, high efficiency, wide application and good quality.

At present, foreign countries have been able to grind and deburr the internal and external surfaces of rotating bodies, flat parts, gear teeth, complex profiles, etc., remove oxide skin on wires and wires, and clean printed circuit boards.

4. Thermal deburring

Thermal deburring (TED) is to burn off the burrs with the high temperature generated after the deflagration of a mixture of hydrogen and oxygen gas or oxygen and natural gas. It is to pass oxygen and oxygen or natural gas and oxygen into a closed container, ignited by a spark plug, so that the mixture deflagrates in an instant and releases a large amount of heat energy to remove burrs. However, after the workpiece undergoes explosive combustion, the oxidized powder will adhere to the surface of the workpiece and must be cleaned or pickled.

5. Mi Lei strong ultrasonic deburring

The powerful ultrasonic deburring technology of Mi Lei is a deburring method that has become popular in recent years. The cleaning efficiency of the accessory is 10-20 times that of ordinary ultrasonic cleaning machines. The cavities are evenly distributed in the sink, so that the ultrasonic does not need to be cleaned. The agent can be completed simultaneously in 5-15 minutes.