6 points for mechanical safety operation

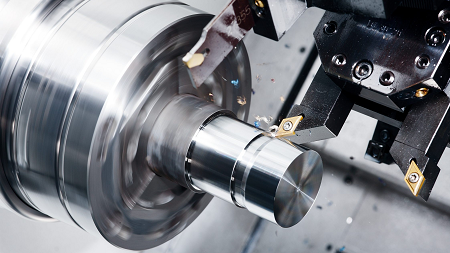

1. What should the miller pay attention to for mechanical safety operation?

The safety items that millers should pay attention to are:

1). When starting to cut, the milling cutter must feed slowly to the workpiece, and there must be no impact, so as not to affect the accuracy of the machine tool or damage the cutting edge of the tool.

2). The processed workpiece should be leveled and clamped to avoid accidents caused by loosening during the work process.

3). Adjustment of speed and direction, as well as correction of workpieces and tools, must be carried out after stopping.

4). Do not wear gloves when working.

5). Use a brush to remove chips on the bed at any time, and stop the machine to remove chips on the milling cutter.

6). After the milling cutter is blunt, stop to sharpen or change the tool, and retract the tool before stopping. Do not stop when the tool does not completely leave the workpiece.

2. What should be paid attention to by planer workers for mechanical safety operation?

The safety items that planers should pay attention to are:

1). The planer should be clamped. There should be a certain gap between the blade and the workpiece before work. Do not take the knife too deep for the first time to prevent damage to the blade or injury.

2). During operation, it is not allowed to stand directly in front of the bull's head planer, let alone check the work in front of the bull's head planer.

3). Adjust the stroke of the machine tool and tighten the bolts that control the stroke.

4). Install a vertical cylindrical protective baffle that can be turned up around the planer table. 5. Concentrate the chip cleaning in a special chip cutter. So as not to cut and puncture the feet.

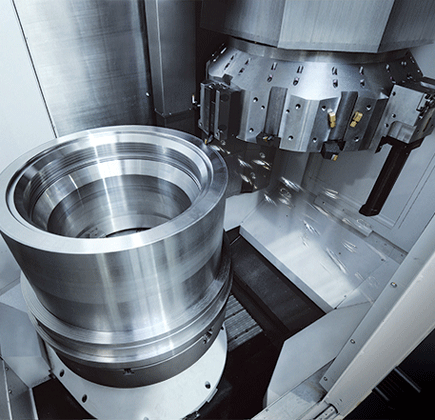

3. What should the grinder worker pay attention to for mechanical safety operation?

The safety matters that grinder workers should pay attention to are:

1). Before driving, check whether the device of the workpiece is correct, whether the fastening is reliable, whether the magnetic suction cup is normal, otherwise, driving is not allowed.

2). When driving, use manual adjustment to leave a proper gap between the grinding wheel and the workpiece, and the initial feed amount is small to prevent the grinding wheel from cracking.

3). Measure the workpiece or adjust the machine tool and clean work should be stopped before proceeding.

4). In order to prevent the debris from hurting people when the grinding wheel is broken, the grinder must be equipped with a protective cover. It is forbidden to use the grinding wheel without a protective cover for grinding.

4. What should be paid attention to by drill press workers for mechanical safety operation?

The safety items that drill press workers should pay attention to are:

1). It is not allowed to wear gloves to operate, and it is strictly forbidden to remove iron filings by hand.

2). The head should not be too close to the drilling machine, and a hat must be worn when working.

3). Tighten the worktable before drilling. The rocker arm should also be tightened before drilling.

4). Do not use excessive force when starting to drill and when the workpiece is about to drill through.

5. What are the main contents of the stamping for mechanical safety operation?

When operating on the stamping equipment, the operator should observe the following safety operating procedures:

1). Before starting operation, you must carefully check whether the protective device is intact and whether the clutch brake device is flexible, safe and reliable. All unnecessary objects on the workbench should be cleaned up to prevent vibration from falling onto the foot switch during work, which may cause accidents due to the sudden start of the punch.

2). When punching small workpieces, no hands are allowed, special tools should be provided, and it is best to install an automatic feeding device.

3). The operator must be careful to control the foot switch. When loading and unloading the workpiece, the foot should leave the footswitch. No outsiders are allowed to stay around the foot switch.

4). If the workpiece is stuck in the mold, use a special tool to take it out. Do not hold it by hand, and remove your foot from the pedal.

6. What should a fitter pay attention to for mechanical safety operation?

The safety items that fitter should pay attention to are:

1). The tools used by fitter must be checked before use.

2). Iron wire protection net should be set on the bench of the fitter. When chiseling, pay attention to the safety of the opposite staff. It is strictly forbidden to use high-speed steel as chisel.

3). When sawing a workpiece with a hand saw, the saw blade should be properly tightened to prevent the saw blade from breaking and hurting people.

4). When using a sledgehammer, you must pay attention to the front and back, left and right, and up and down environmental conditions. It is strictly forbidden to stand within the scope of the sledgehammer's movement.

5). When working in multiple layers or crossing, pay attention to wearing a safety helmet and follow the unified command.

6). After the equipment is overhauled, all safety protection devices, safety valves and various sound and light signals must be restored to their normal state.