7075 Aluminum and Properties,Strength and Uses

7075 Aluminum introduction

7075 ALUMINUM refers to a commonly used 7-series aluminum alloys. Among the more common aluminum alloys, the best strength is 7075 alloy, which is commonly used in CNC cutting parts. It is suitable for flying machine frames and high-strength accessories. The 7 series aluminum alloy contains zinc and magnesium elements. Zinc is the main alloying element in this series, so the corrosion resistance is quite good, and a little magnesium alloy can make the material reach a very high strength after heat treatment.

The 7-series aluminum alloy belongs to the Al-Zn-Mg-Cu series, and it’s super-hard aluminum. This alloy is an ultra-high strength deformed aluminum alloy that has been widely used in the aircraft manufacturing industry in the late 1940s and is still widely used in the aviation industry.

7075 Aluminum chemical composition

|

Aluminum 7075 Component |

Al |

Cr |

Cu |

Fe |

Mg |

Mn |

Other, each |

Other, total |

Si |

Ti |

Zn |

|

Wt. % |

87.1-91.4 |

0.18-0.28 |

1.2-2 |

Max 0.5 |

2.1-2.9 |

Max 0.3 |

Max 0.05 |

Max 0.15 |

Max 0.4 |

Max 0.2 |

5.1-6.1 |

7075 Mechanical properties

|

Material- 7075 aluminum |

Temper |

Thickness (in) |

7075 aluminum Tensile Strength (ksi) |

7075 aluminum Yield Strength (ksi) |

7075 aluminum Elongation % |

|

Alloy 7075 Sheet |

T6 |

0.125 - 0.25 |

78 |

69 |

8 |

|

Alloy 7075 Sheet |

T651 |

0.25 - 0.50 |

78 |

67 |

9 |

|

Alloy 7075 Sheet |

T651 |

0.5 - 1.0 |

78 |

68 |

7 |

|

Alloy 7075 Sheet |

T6 |

0.188 - 0.25 |

75 |

64 |

8 |

|

Alloy 7075 Sheet |

T651 |

0.25 - 0.50 |

75 |

65 |

9 |

|

Alloy 7075 Sheet |

T651 |

0.5 - 1.00 |

78 |

68 |

7 |

7075 Aluminum Physical properties

|

7075 aluminum Characteristic |

English |

Metric |

|

Nominal Density (68° F / 20°C) |

0.101 lbs./ in ³ |

2.80 Mg/m³ |

|

Melting Range |

990° F - 1175° F |

532°C - 635 °C |

|

Specific Heat (212 °F / 100°C |

0.23 BTU/lb - °F |

960 J/kg-°K |

7075 Product Characteristic

1. High strength heat treatable alloy;

2. Good mechanical properties;

3. Good usability;

4. Easy to process and good wear resistance;

5. Good corrosion resistance and oxidation resistance.

The main application of 7075 aluminum alloy:

Aerospace industry, blow molding (bottle) molds, ultrasonic plastic welding molds, high ball heads, shoe molds, paper molds, foam molding molds, wax removal molds, fixtures, mechanical equipment, mold processing, high-end aluminum alloy bicycles Frame. Especially used to manufacture aircraft structures and other high-stress structures that require high strength and strong corrosion resistance

7075 heat treatment type

7075-O

Un-heat-treated 7075 (7075-0 temper) has a maximum tensile strength of no more than 280 MPa (40,000 psi), and maximum yield strength of no more than 140 MPa (21,000 psi).

7075-T6

T6 temper 7075 has an ultimate tensile strength of 510–540 MPa (74,000–78,000 psi) and yield strength of at least 430–480 MPa (63,000–69,000 psi). It has a failure elongation of 5–11%.

The T6 temper is usually achieved by homogenizing the cast 7075 at 450 °C for several hours, quenching, and then aging at 120 °C for 24 hours.

7075-T651

T651 temper 7075 has an ultimate tensile strength of 570 MPa (83,000 psi) and yield strength of 500 MPa (73,000 psi). It has a failure elongation of 3–9%.

7075-T7

T7 temper has an ultimate tensile strength of 505 MPa (73,200 psi) and a yield strength of 435 MPa (63,100 psi). It has a failure elongation of 13%.

7075-RRA

The retrogression and reage (RRA) temper is a multistage heat treatment temper. Starting with a sheet in the T6 temper, it involves overaging past peak hardness (T6 temper) to near the T7 temper.

RRA treatments can be accomplished with many different procedures.

7075 equivalent material from different nation

|

EU |

USA |

Germany |

Japan |

France |

England |

Italy |

Poland |

Czechia |

Austria |

Russia |

Inter |

|

EN |

- |

DIN,WNr |

JIS |

AFNOR |

BS |

UNI |

PN |

CSN |

ONORM |

GOST |

ISO |

|

ENAW-AlZn5.5MgCu |

A97075 |

3.4365 AlZnMgCu1.5 |

7075 |

7075 |

7075 |

P-AlZn5.8MgCuCr |

AlZn6Mg2Cu |

424222 |

AlZnMgCu1.5 |

V95 |

AlZn6MgCu |

American Standard: 7075 / A97075 AA / UN

China National Standard: 7A09 GB / T3190--1996

Japanese Standard: A7075 JIS H4000-1999 JIS H4080-1999

Russian Standard: B95 / 1950 rocT 4785-1974

EN: EN AW-7075 / AlZn5.5MgCu EN573-3-1994

German standard: AlZnMgCu1.5 / 3.4365 DIN172.1-1986 / w-nr

French standard: 7075 (A-Z5GU) NFA50-411 NFA50-451

British Standard: 7075 (C77S) BS 1470-1988

7075 different raw material specifications:

1. Aluminum tube: (diameter Φ6-φ260, wall thickness 0.3-40mm) alloy aluminum tube, seamless aluminum tube, large-diameter aluminum tube, thick-walled aluminum tube, alumina tube, aluminum flat tube, aluminum square tube, coil , Fine drawn aluminum tube.

2. Aluminum plate: (thickness 0.5-300mm; width 50-2000mm) hot-rolled aluminum plate, ultra-wide ultra-thick aluminum plate, alloy aluminum plate for mold, aluminum plate for automobile and ship

3. Aluminum rod: (diameter Φ6-Φ300mm) pure aluminum rod, alloy aluminum rod, cast rod; aluminum round rod, square rod, flat rod, hexagonal rod.

4. Aluminum row: (thickness: 2.0-25mm; width: 20-380mm) electrical aluminum row, aluminum bus bar, large-size special aluminum row

5. Pattern aluminum plate, crimped aluminum plate: (thickness 1mm-6mm) size five bar type, pointer type, diamond type, orange peel pattern, etc .; mirror pattern aluminum plate.

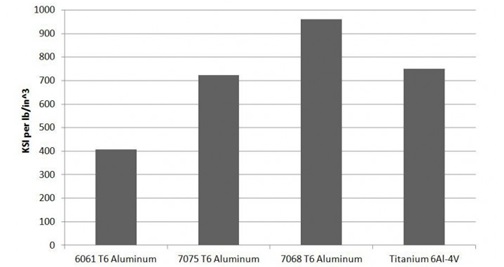

Which is stronger aluminum?

7068 aluminium alloy is one of the strongest aluminium alloys. 7068-T6511 has typical ultimate tensile strength of 710 MPa (103 ksi) versus 7075-T6511’s ultimate tensile strength of 640 MPa (93 ksi). Typical yield strength for aluminium alloy 7068 is 683 MPa (99.1 ksi) versus 590 MPa (86 ksi) from 7075-T6511.

Which aluminum is hardest?

7068 aluminium alloy is one of the strongest aluminium alloys. 7068-T6511 has typical ultimate tensile strength of 710 MPa (103 ksi)

Below picture you can know aluminium alloys 7068 is more harder than 7075 and Titanium. But since7068 aluminium alloy is very expensive and not easily to get. We usually use 7075 for production.

What is the hardest grade of aluminum?

Aluminum 2024 and Aluminum 7075 is more hard than other material. 2024-T351 tensile strength is 470 MPa and 7075-T651 tensile strength is 570 MPa.

And 7068-T6511 is the most hard aluminum with tensile strength 710 Mpa.

Comparing different Aluminum alloys 2024 VS 6061, 6061 VS 6052, 2024 VS 7075

| Aluminum Grade | Temper Status | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation % |

| 2024-O | 140–210 MPa(21–30 ksi) | 97 MPa(14,000 psi) | 10-25% | |

| 2024-T3 | 400-430 MPa(58-62 ksi) | 270-280 MPa(39-40 ksi) | 10-15% | |

| 2024-T351 | 470 MPa(68 ksi) | 280 MPa(41 ksi) | 0.2 | |

| 5052-O | 195 MPa(28 ksi) | 89.6 MPa(13 ksi) | ||

| 5052-H32 | 228 MPa(33 ksi) | 193 MPa(28 ksi) | ||

| 5052-H34 | 262 MPa(38 ksi) | 214 MPa(31 ksi) | ||

| 5052-H36 | 276 MPa(4 ksi) | 241 MPa(35 ksi) | ||

| 5052-H38 | 290 MPa(42 ksi) | 255 MPa(37 ksi | ||

| 6061-O | O | 150 MPa(22 ksi) | 83 MPa(12 ksi) | 10-18% |

| 6061-T4 | T4 | 180 MPa(26 ksi) | 110 MPa(16 ksi) | 10-16% |

| 6061-T6/T651 | T6/T651 | 310 MPa(45 ksi) | 270 MPa(39 ksi) | 8-10% |

| 7075-O | O | 280 MPa(40 ksi) | 140 MPa(21 ksi) | 9-10% |

| 7075-T6 | T6 | 510–540 MPa(74–78 ksi) | 430–480 MPa(63–69 ksi) | 5-11% |

| 7075-T651 | T651 | 570 MPa(83 ksi) | 500 MPa(73 ksi) | 3–9% |

| 7075-T7 | T7 | 505 MPa(73 ksi) | 435 MPa(63 ksi) | 0.13 |

| 7005 | 350MPa | |||

| 7022 | 370 Mpa | |||

| 7022_T651 | T651 | 440 Mpa | ||

| 7068-T6511 | T6511 | 710 MPa(103 ksi) | 683 MPa(99.1 ksi) |

Summary

This article briefly introduces the performance, strength and application of 7075 aluminum. And compare the hardness of different aluminum alloys.