All about Horizontal Milling Machine

What is a horizontal milling machine?

Most milling machines move the object being shaped and the tool doing the shaping. This puts these machines in a unique class, as most manufacturing equipment typically only do one or the other. There are two basic styles of milling machine: the vertical and the horizontal milling machine. They differ in design and general usage.

A horizontal milling machine is one of the two basic styles of milling equipment. These machines specialize in a process called arbor milling, which involves the rapid removal of material from a source object. These machines were the original milling machine style, with vertical milling only coming into prominence many years later. While a horizontal milling machine is still commonplace in most large manufacturing centers, vertical machines utilizing computer numerical control (CNC) are becoming more common all the time.

A milling machine is a piece of manufacturing equipment. The horizontal milling machine came into use during the early 1800s, and the basic design of a common modern machine is nearly the same as this original model. These machines may be small enough to fit on a kitchen table or as large as entire rooms, depending on the size of the item being manufactured. These machines take an initial object and remove bits, drill holes or shape contours until it is a specific size, shape and weight.

The horizontal milling machine is a kind of machine tool with 12 speeds. It can be used to processvarious planes, bevels, grooves, etc. with various cylindrical milling cutters, wafer milling cutters,angle milling cutters, forming milling cutters and end milling cutters.

The composition and function of horizontal milling machine

(1) Spindle box. It fixes du on the left end of the machine body zhi, and installs the dao spindle in the spindle box (the spindle is hollow, which can not only be used for the processing of longer bars and the laying of machine lines, but also increase the rigidity of the spindle), through the chuck Wait for the fixture to clamp the workpiece. The function of the headstock is to support and drive the main shaft so that the main shaft drives the workpiece to rotate at the specified speed.

(2) Bed saddle and tool rest components. It is located in the middle of the bed and can move longitudinally along the tool post track on the bed. The tool rest part is located on the saddle, and its function is to clamp the turning tool and make the turning tool move longitudinally, horizontally or diagonally.

(3) Tailstock. It is located on the tailstock rail of the bed and can be adjusted longitudinally along the rail. The function of the tailstock is to support the workpiece with the rear center. Drills and other processing tools can also be installed on the tailstock for hole processing.

(4) Feeding box. It is fixed on the left front side of the bed and the bottom of the spindle box. Its function is to change the pitch of the machined thread or the amount of motorized feed.

(5) Slide box. It is fixed at the bottom of the tool holder part, and can drive the tool holder to do longitudinal, horizontal feed, rapid movement or thread processing together. Various operating handles and buttons are installed on the slide box so that workers can conveniently operate the machine tool during work.

(6) Bed. The bed is fixed on the left leg and the right leg. The bed is the basic support of the machine tool. The main parts of the machine tool are installed on the bed, and the bed keeps them in an accurate relative position when working.

Horizontal milling machine features

1. The spindle sleeve can be manually micro-injected, and has a limit device, and the millinghead can be adjusted smoothly and counterclockwise by 45;

2. The worktable can be manually fed vertically and horizontally and vertically up and down,while horizontally and vertical maneuvering can be realized in vertical and horizontal directions;

3. It adopts 1200mm extended slider and 1 500mm extended table. The longitudinal stroke ofthe table can reach 1000mm, the stroke is long and the stability is stronger.

4. Both the main drive and the feed adopt a gear shifting mechanism, and the speed

adjustment range is wide;

5. The main shaft bearing adopts tapered roller bearing, which has strong bearing capacityand energy consumption braking. It has large braking torque, quick stop and reliable

braking.

6. The rectangular guide rail has good stability;

7. The table and the guide rail are quenched by super audio and have greater strength.

Horizontal lifting table milling machine features

· The spindle has good steel and strong bearing capacity.

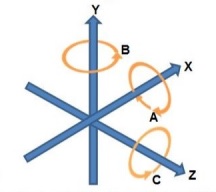

· Worktable X, Y, Z three-way motorized feed

· X, Y,Z three-way guide rail sub-audio quenching, precision grinding

· The manual lubrication device forcibly lubricates the lead screw and the guide rail.· Special accessories - vertical milling heads can be configured for vertical milling.

Vertical horizontal universal lifting table milling machine features

· It can realize the processing functions of vertical and horizontal milling.

· Two-section rotary milling head and spindle can be rotated and adjusted at any angle.. Can be used to machine shells and molds.

. Worktable x, Y to maneuver feed.

The main application of horizontal milling machine

The horizontal milling machine has stable quality. It can process various planes, bevels, grooves, etc. with various cylindrical milling cutters, disc milling cutters, angle milling cutters, forming milling cutters and end milling cutters. If you use appropriate milling machine accessories, you can process special-shaped parts such as gears, cams, arc grooves, and spiral surfaces. It is equipped with milling machine accessories such as universal milling heads, round tables, indexing heads, etc., and it can also be centered after using boring bars. , Hole processing for small parts. Adding an end milling head can be used for cutting with an end milling cutter. (The end milling head is a special accessory) can further expand the range of machine tools. This machine tool is suitable for various machining industries.

The advantages of horizontal milling machines are as follows:

1. The machine has good rigidity and can carry heavy load cutting.

2. The spindle motor of the horizontal milling machine has high power and a wide range of changes, giving full play to the tool's efficiency and high-speed cutting.

3. Wear-resistant castings are made of vanadium-titanium wear-resistant cast iron, and important parts are made of high-quality alloy steel, which is stable and durable.

4. The machine tool has a complete lubrication system.

5. The horizontal milling machine can be equipped with a digital display device according to user needs. The product is easy to operate and reliable in performance. Various cylindrical milling cutters, disc milling cutters, angle milling cutters, forming milling cutters and end milling cutters can be used to process various planes, bevels, grooves, etc.