Benefits for CNC lathe machine

Mechanical processing plants generally have two types of equipment, ordinary lathes and CNC lathes machine. CNC lathes machine are the most advanced types of lathes today. It has a very different and very simple way to set up and operate the machine, and it also integrates very advanced methods and processes. In fact, they have now quickly replaced the older types of lathes in several production units and processing plants. Because they can perform many operations that other lathes cannot, they are now widely used by many users around the world.

There are many benefits to using CNC lathes machine, such as powerful shaft drives, feedback control to monitor and maintain tool position, higher speeds, and repeated movements of complex machines. In addition, once the program is verified, the relevant operations can be re-set quickly, instead of making any tedious manual adjustments. CNC lathes machine can also accurately cut curved shapes without using any special type of forming tools. This can be achieved by programming the speed of the two motion axes and the spindle at the same time.

The CNC lathe is easy to set up and easy to operate. They mainly help implement innovative manufacturing methods in order to obtain the maximum benefit from the latest technology. Machine components are pre-set, and tool paths are pre-planned through CAD and CAM processes. Then, the programmed files will be tested and loaded on the computer. Thereafter, the operator issues relevant commands to activate the necessary parts of the machine.

Another major advantage of CNC lathes machine is ease of setup, operation, repeatability and accuracy. They are designed to use modern tools, and after setting up the machine, it can work continuously for a long time under the occasional supervision of the operator. The CNC lathe is electronically controlled through a computer menu interface. A virtual view of related programs and processes can be displayed on the machine. In addition, users can even modify the program as needed. Must have a general understanding and basic knowledge of CNC lathes machine. Therefore, machine installers and operators should have a high level of skill to perform the required process. These lathes are usually set up and operated by the same person. And the operator can easily supervise a small batch of machines.

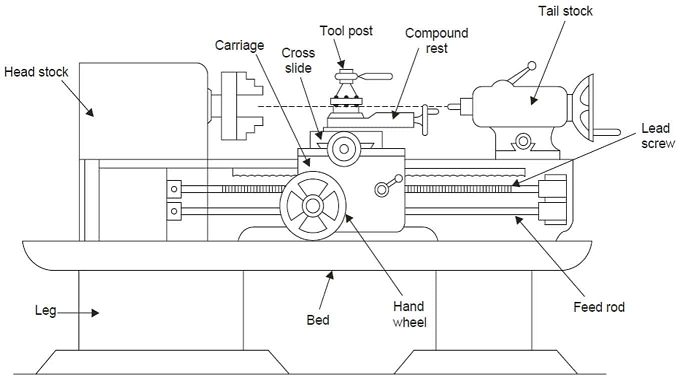

The design of CNC lathes machine is usually different and depends on the specific manufacturer. But they all have some common features. Now machines of various specifications and sizes are available on the market. These modern machines are completely enclosed to maintain industrial safety standards. In addition, due to the rapid development of technology, these CNC lathes machine have been continuously upgraded accordingly. They include different kinds of user interfaces, which sometimes cause confusion and are difficult for operators to learn. Therefore, all machine tool users should be properly trained to fully familiarize themselves with the latest technology and obtain the maximum benefit of CNC lathes machine.