CNC Definition, What is CNC meaning?

CNC Definition. What is CNC?

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing G Code. CNC can control the motions of the workpiece or tool, the input parameters such as feed, depth of cut, speed, and the functions such as turning spindle on/off, turning coolant on/off.

CNC Application

CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly automated machine tools such as turning center and machining center which change the cutting tools automatically under CNC control.

The benefits of CNC

(1) High accuracy in manufacturing,

(2) Short production time,

(3) Greater manufacturing flexibility,

(4) Simpler fixture,

(5) Contour machining

(6) Reduced human error.

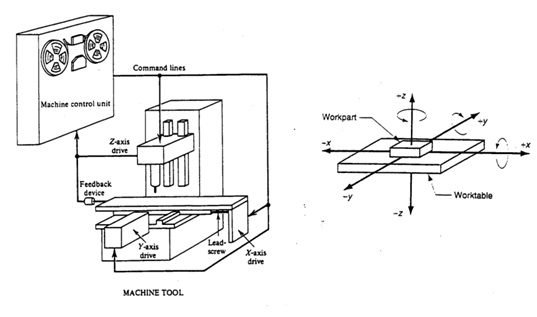

ELEMENTS OF A CNC

A CNC system consists of three basic components

1. Part program and G Code

The part program is a detailed set of commands to be followed by the machine tool. Each command specifies a position in the Cartesian coordinate system (x,y,z) or motion (workpiece move or cutting tool move), machining parameters and on/off function. Part programmers should have good knowledge with machine tools, machining processes, effects of process variables, and limitations of CNC controls. The part program is written manually or by using computer assisted language such as G Code.

Cartesian coordinate system (x,y,z)

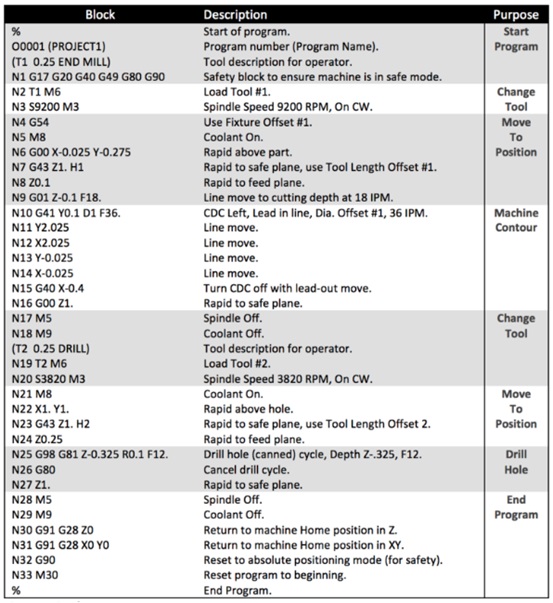

G Code Introduction

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. It is a set of instructions that tells a CNC machine where – and how – to move. These instructions are called G-Code.

Take for example this line of code:

G01 X1 Y1 F20 T01 M03 S500

In this single line we’re giving the machine a series of instructions:

G01 – Perform a linear feed move

X1/Y1 – Move to these X and Y coordinates

F20 – Move at a feed rate of 20

T01 – Use Tool 1 to get the job done

M03 – Turn the spindle on

S500 – Set a spindle speed of 500

The goal of every G-code program is to produce parts in the safest and most efficient way possible. To achieve this you’ll typically find G-code blocks arranged in a very specific order like this:

1. Start the CNC program

2. Load the required tool

3. Turn the spindle on

4. Turn the coolant on

5. Move the cutting tool to the position above a part

6. Start the machining process

7. Turn the coolant off

8. Turn the spindle off

9. Move away from the part to a safe location

10. End the CNC program

Below are a G Code example.

2. Machine Control Unit (MCU)

Is a microcomputer that stores the program and executes the commands into actions by the machine tool. The MCU consists of two main units: the data processing unit (DPU) and the control loops unit (CLU).

3. Machine tool (lathe, drill press, milling machine etc)

The CNC machine tool include CNC Plasma Cutting Machine, CNC Laser Cutting Machine, CNC Milling Machine, CNC Router Machine and CNC Lathe Machine.

Summary

This article introduce the CNC Definition, CNC Element, G Code and CNC machine tool.