What is CNC Mill? What is CNC milling machine? What’s the difference between CNC Mill and CNC machine center?

What is CNC Mill? What is CNC milling machine?

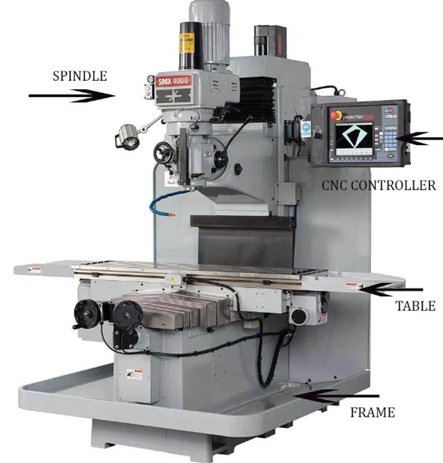

CNC Mill or CNC Milling machine have the same meaning. CNC mill is the most widely used CNC machine tool. CNC Mill or CNC Milling machine performs mainly milling, which is very similar to drilling and cutting. In the most basic case, CNC mill uses a rotating cutting tool to remove excess material from the workpiece when it is fed into the milling tool.

Rotating cylindrical tools in CNC milling machines can be moved along multiple axes to create unique shapes, slots, holes and details in parts. Most machine tools now have three to five axes, allowing the most advanced cutting tools to perform complex machining with extremely complex geometries.

Modern CNC milling machines can be used as both horizontal machining centers and vertical machining centers for assembly. In addition to metal processing, plastic, ceramics and composite materials can also be processed.

What is CNC Milling?

CNC stands for computer numerical control, which can achieve high precision and automation, and convert specific digital codes into Cartesian coordinates, thus ensuring that each manufactured part is produced with consistent accuracy. There are many options for CNC milling operations. Each type has its unique advantages and applications.

• Face milling uses tools with teeth on both the outer circumference and the end face. This tool is used to make flat surfaces, smooth contours, and produce higher quality than other forming methods.

• Plane milling can form large pieces of material. The wider cutting teeth can shape a large area of material, while the narrower cutting teeth can perform deeper cutting.

• Angle milling can adjust the angle of the tool to produce chamfers, saw teeth, grooves and other angle features.

• Form milling uses forming tools to process circular cavities, contours and complex patterns.

• Straddle milling is the process of cutting multiple pieces with one machine. The cutters are connected by cutter bars and move simultaneously on adjacent surfaces.

• Wheel milling uses multiple tools on one machine. These cutting tools are able to perform the same actions, creating complex parts in less time.

• Contour milling refers to the process of cutting a vertical or angled path on a workpiece.

How does CNC Mill work?

Milling is the process of cutting and drilling materials. The milling machine uses a rotating cylindrical tool called a milling cutter. The milling cutter is fixed in the spindle and can vary in form and size.

The main difference between a milling machine and any other drilling machine is the ability to cut at different angles and move along different axes. Therefore, there are several milling machines, which are specified by the number of motion axes:

• 2 axis milling machine can cut holes and slots on X axis and Z axis. In other words, this machine will only cut in horizontal and vertical directions (but only in one direction).

• The 3-axis milling machine adds the y-axis. This is the most common type of milling machine. You can cut vertically in any direction, but objects like balls will need to be cut in half at a time. This is because even if three shafts are used, it cannot be cut from below.

• 4-axis milling machines are more complicated because they increase the ability to rotate the x-axis, similar to lathes.

• The 5-axis milling machine has rotation functions on both the x-axis and y-axis. This is the most complete milling machine you can have. It allows you to shape bones, aerospace structures, car models, medical products, and almost all other shapes you can imagine.

• The CNC milling machine can have any number of axes (2 to 5), but it can be operated by a computer. No manual operation is required.

The advantages of CNC Mill or CNC Milling Machine

CNC machine tools have many advantages:

1. Reliability -The machine operates reliably; whether it is a working day, weekend or holiday. Their only stop time is when maintenance, repair or downtime is required.

2. High output -they usually complete a lot of work in a relatively short time and are flexible.

3. Less labor -when the machine is running, all they need is some supervision and regular maintenance. They are programmed and can usually work on their own.

4. Same products -Despite the high speed of these machines, they are able to produce uniform products with few errors.

What kind of material can CNC Mill use?

CNC Mill can work on different material:

• Alloy and tool steel (eg 4140, 4340, D2, A2, O1): wide range of applications

• Aluminum 6061: aviation grade, affordable and easy to process

• Brass C360: excellent processability and surface finish

• Low carbon steel (eg 1018, 1045, A36): widely used, high cost performance

• Stainless steel (eg 304, 316, 2205): corrosion and chemical resistance

• Nitrile butadiene styrene (ABS): toughness and impact resistance

• High density polyethylene (HDPE): high strength to density ratio

• Nylon 6: abrasion resistance and chemical resistance

• PEEK: high mechanical and chemical resistance

• Polycarbonate (PC): strong and easy to process

• Delrin: designed for large mechanical loads

• Teflon: hydrophobic and low coefficient of friction

What’s the difference between CNC Mill VS CNC machine center?

CNC Mill or CNC milling machine is an automatic processing equipment developed on the basis of a universal milling machine. The main working method is to control the milling work through the CNC, which is more efficient and easier to operate than the general milling machine.

The CNC machine center is developed on the basis of the CNC Mill or CNC milling machine. The increased automatic tool magazine can process more complex parts. The biggest difference between a CNC machining center and a CNC milling machine is that the CNC machining center has the ability to automatically change machining tools. The CNC milling machine has only three axes, and the CNC machining center can be four-axis or five-axis linkage, which is more widely used than the CNC milling machine.

Summary

This article introduces the CNC Mill, CNC Milling Machine, CNC Milling Process, CNC Milling material and how CNC Mill works.