6 Important Features of CNC Milling Machine You Must Know

CNC Milling machine is a very important equipment in Cnc machine shop. The surface shape of the milling parts is generally composed of straight lines, arcs, or other curves. The operators of the ordinary milling machine constantly change the relative position between the tool and the workpiece according to the requirements of the drawing, and then cooperate with the selected milling cutter speed to make the tool cut the workpiece and process various workpieces of different shapes.

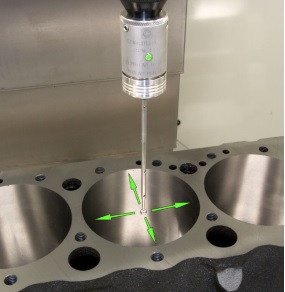

CNC milling machine divides the motion coordinates of the tool and the workpiece into the smallest unit quantity, that is, the smallest displacement. According to the requirements of the workpiece program, the CNC system moves each coordinate by a few minimum displacements, so as to realize the relative movement of the tool and the workpiece to complete the processing of the part.

In addition to the features of ordinary milling machine, CNC milling machine has the following features.

1. The parts have strong adaptability and good flexibility, and can process parts with particularly complicated contour shapes or difficult to control dimensions, such as mold parts and shell parts.

2. It can process parts that can not be processed or difficult to be processed by ordinary machine tools, such as complex curve parts described by mathematical models and three-dimensional space curved parts.

3. It can process the parts that need to be processed in multiple procedures after one clamping and positioning.

4. High processing precision, stable and reliable processing quality, the pulse equivalent of the numerical control device is generally 0.001mm, and the high-precision numerical control system can reach 0.1μm. In addition, the numerical control processing also avoids the operation errors of the operators.

5. The high degree of production automation can reduce the labor intensity of the operator. Conducive to automation of production management.

6. It has high production efficiency. CNC milling machines generally do not require the use of special process equipment such as special fixtures, and only need to call the processing program, clamping tool and tool data adjustment stored in the CNC device when replacing the workpiece, thus greatly reducing production Cycle, secondly, the CNC milling machine has the functions of milling machine, boring machine and drilling machine, which makes the process highly concentrated and greatly improves the production efficiency. In addition, the spindle speed and feed speed of the CNC milling machine are continuously variable, so it is conducive to choose the best cutting amount.

After reading this article about CNC Milling Machine, do you think it makes sense? Or what other opinions do you have? Welcome to share your views and comments!