The Differences between Dry Milling and Wet Milling, Dry Milling VS Wet Milling

The milling process is essentially an intermittent machining process. This causes the temperature at the cutting edge to fluctuate continuously between high temperatures (about 1000 ℃) and low temperature. As the cutting edge cuts in and out, the temperature change will increase. As a result, the cutting edge is subject to thermal shock and periodic stress, which can lead to possible cracks, which in the worst case can cause the effective life of the tool to end prematurely. Should we choose dry or wet milling? Which is more beneficial to tool life?

Thermal cracks on the cutting edge

Influence of Cutting Fluid

The cutting fluid has two main functions. One is to cool the machining process, increase the output of parts, at the same time reduce the wear of the tool and have a lubricating effect, improve the surface roughness and improve tolerance control. The second function is to wash away the hardened chips away from the cutting zone, reduce the cutting nodules on the tool, and reduce the amount of dust scattered in the air for health.

What is Dry milling?

Dry milling is a method of milling under the condition of no cold liquid consciously without using cutting fluid to protect the environment and reduce costs. Dry milling is not simply to stop using cutting fluid, but to stop using cutting fluid while ensuring high efficiency, high product quality, high tool durability and reliability of the cutting process, which requires dry milling with excellent performance Tools, machine tools and auxiliary facilities replace the role of cutting fluid in traditional milling to achieve true dry milling.

Dry milling can extend the life of the cutting edge. The temperature will indeed change, but it will remain within the design range of the carbide material. The rough milling process should always be carried out without using cutting fluid.

What is Wet Milling?

Wet milling is milling using cutting fluid. Although dry milling can extend the tool life, the cost of cutting fluid treatment, health and safety issues are attracting more and more attention. The use of dry processing is a very valuable saving in technology, but in some cases, only wet processing can be selected.

There are some exceptions where cutting fluid should be used:

1) Stainless steel and aluminum alloy finishing-used to prevent metal particles from sticking to the surface structure

2) Milling of superalloys at low cutting speeds-used to lubricate and cool parts

3) Cast iron milling, used to wet and wash away dust, to protect the environment and health and ensure the accuracy of parts

4) Milling of thin-walled parts to prevent geometric deformation

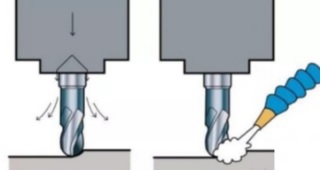

5) When machining deep cavities, a small amount of lubrication system (ie compressed air containing a small amount of special oil) can be used to assist in chip removal.

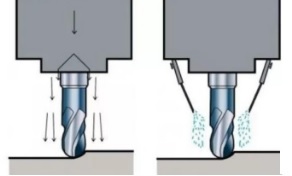

Compressed air and oil mist

In the micro-lubrication system, the "oil mist" amount is only a few milliliters of oil per hour, and is discharged through the ordinary filter ventilation system.

Inner coolant and outer coolant

If wet milling must be performed, a sufficient amount of cutting fluid should be used.