What is Lathe Facing in lathe machine

What is lathe facing?

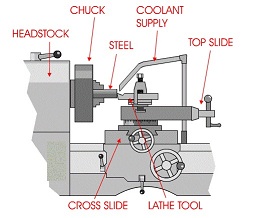

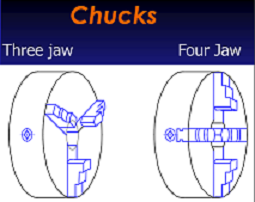

Facing is the basic process making a flat and smooth surface at the end of the work piece by removing metal from the end of it. Generally speaking, the workpiece is round, we can face it with regular tools. If you face rectangular or odd-shaped work to form cubes and other non-cylindrical shapes, you could choose a 4-jaw chuck.

How to do lathe facing to the end of a part?

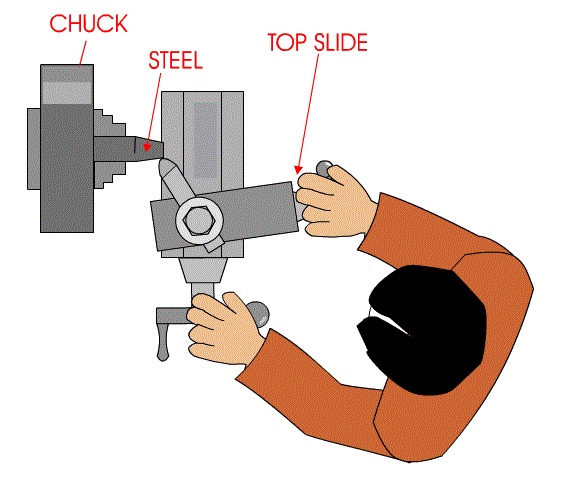

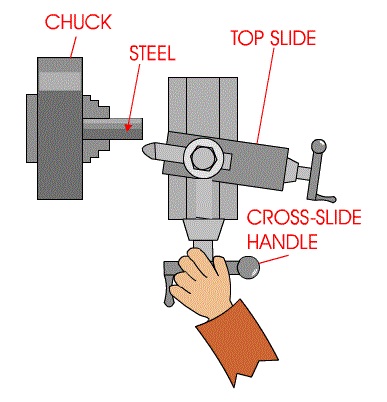

The first thing you need to do is to set the tool up. Loosen the tool holder, angle a tool out from the end of the stock about 10 to 15 degrees just to give a little bit of clearance on the end. We also need to center the tool bit vertically.

How to use a lathe facing Tool on a Lathe machine/turning machine?

Fixed the workpiece on the CNC lathe machine and the facing tool is mounted into the tool holder of the lathe carriage, when the tool rotating in the jaws of the chuck, it will feed perpendicularly across the part's rotation axis, to cut the workpiece to the required length accurately. CNC machines can provide power feed, which instead of hand feed to obtain smoother surface finish.

What factors will affect the quality of lathe facing operation?

There are many factors that will affect the quality and efficiency of the lathe end facing processes, such as the cutting tool speed and feed, size and material, the type of material to be processed, and the method of workpiece clamping. We can choose to rough machining or to precision finish according to the material to be removed.

What's the difference between lathe facing and milling facing?

1. Lathe facing is done with the turning lathe, while milling facing performed on the milling machine.

2. In lathe facing, the part is rotating, and the cutting tool is stationary in the same position, while in milling facing, the facing tool rotates against the fixed workpiece.

3. The workpiece is generally round in lathe facing, while you can face rectangular or odd-shaped material to fabricate parts in cubes and other non-cylindrical shapes.

4. Lathe facing is a type of turning operation, which includes boring, grooving, reaming, and more, while milling facing is working reversed to turning.