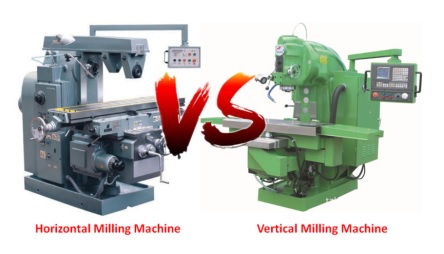

Horizontal vs Vertical Milling Machine

As a common machining process, milling involves the use of a machine, known as a milling machine, to remove material from a stationary workpiece using a rotating cutting tool. With milling, the workpiece remains stationary, whereas the cutting tool rotates. As the rotating cutting tool presses against the workpiece, it removes material.

While all milling machines follow this same basic formula, there are different types of milling machines, each of which has its own unique characteristics. In this article, we’ll look at horizontal milling machines and vertical milling machines, comparing these two main types and understanding their differences.

What Is a Vertical Milling Machine?

A vertical milling machine is the most commonly used type and features a vertically oriented cutting head or spindle, holding as well as rotating the cutting tool against the workpiece. Since the cutting head is affixed in a vertical orientation, other machine parts will shift along a single or more axes to move the material in the right position for proper milling. The spindle will move up and down, removing material by pressing against the workpiece.

Types of vertical milling machine

Vertical mills are ideal for projects worked on a single side like operating with large metal plates and sinking dies. There are basically two vertical milling machines types: turret milling machines and bed milling machines—the function a little differently from each other as well as offer unique advantages.

Turret Mill: In a turret mill, the spindle remains in a fixed location, and the bed portion of the machine that holds the material moves horizontally or vertically. With the ability to manipulate the position of the material in both directions, a turret mill is extremely versatile. However, these mills are usually limited to projects relating to smaller pieces, as the two-axis movement can be challenging with larger pieces of material.

Bed Mill: A bed mill can only move the material along the horizontal axis. In this type of milling machine, the spindle is restricted to the vertical axis but can move up and down as needed. The movement of the spindle combined with the horizontal movement of the bed allows milling of a wide variety of shapes and depths. A bed mill is better suited to projects requiring heavy, large pieces than a turret mill is.

Features of Vertical Milling Machine

1. Popularity: These machines make up most of the milling machinery in the country. Typically, they are more affordable compared to horizontal mills, making it a shrewd investment that pays ten times over. Because of its low upfront cost, production cost savings will be passed to clients. Given how prevalent these types of mills are, skilled operators in the industry are surging.

2. Ease of Operation: The structural design of vertical mills gives operators better visibility while working. This will give the operator(s) a higher chance of spotting and correcting potential problems easily as the milling commences. Also, programming is made simple by the user-friendly CNC controls. So operators won’t waste time setting up and programming; instead, they will concentrate on making sure that the specifications of the project are met to the highest of standards. Now, no matter what, milling machines should only be operated by experts with the experience to safely complete the project.

3. Production Benefits: The visibility provided by vertical mills is excellent for finishing large plate metal fabrication. Given how easy it is to use the machine, it’s better suited for less complicated jobs that need low quantities. This machine is the ideal solution for quick milling jobs.

What Is a Horizontal Milling Machine?

Horizontal milling machines feature a similar design in which a spindle containing a rotating cutting tool presses against a workpiece to remove material from the workpiece. With that said, horizontal milling machines differ from their vertical counterparts in several ways. The biggest difference between these two types of milling machines is the orientation of the spindle. With vertical milling machines, the spindle features a vertical orientation. With horizontal milling machines, the spindle features a horizontal orientation. In other words, horizontal milling machines mount the cutting tool on a horizontally oriented spindle that’s able to selectively remove material from the stationary workpiece.

Furthermore, horizontal milling machines usually feature different cutting tools than vertical milling machines. While vertical milling machines usually have long and thin cutting tools, horizontal milling machines have shorter and thicker cutting tools.

Horizontal milling machines are able to perform heavier, deeper cuts than vertical milling machines. As a result, manufacturing companies often use them to cut grooves or slots into workpieces. Hopefully, this gives you a better understanding of the differences between vertical milling machines and horizontal milling machines.

Features of Horizontal Milling Machines

1. Chip Evacuation: Due to the horizontal mills’ setup, when cutting is ongoing, gravity will aid in pulling the chips out. That will translate in the end products having cleaner surface finishes and need less fabrication or production later on.

2. Solid Construction: Horizontal mills are constructed more heavily and can deal with bigger volume production jobs. The machine parts are built to last longer. Their rigid construction translates to the machine vibrating less, deflecting less and functioning more smoothly than vertical mills.

3. Productivity: The integrated pallet changer and 4th Axis Tombstone massively extrapolate the productivity of these machines, a feature that’s perfect for large quantities and complex workloads. The mechanical design of the horizontal mill allows it to do work equaling that of three machining tools. This is ideal for production cost and time efficiency.

Although they have similarities, horizontal mills are better suited for more complicated projects compared to vertical mills. These machines will complete the tasks much quicker, though it may require a significant financial boost.

The difference between Horizontal vs Vertical Milling Machine

|

No. |

Vertical Milling Machine |

Horizontal Milling Machine |

|

1 |

It is versatile and widely used. |

It is less popular. |

|

2 |

A spindle axis is aligned vertically. |

A spindle axis is placed in a horizontal direction. |

|

3 |

It is cheaper in price. |

It is a little bit costly. |

|

4 |

We get a poorer surface finish. |

We will get the best surface finishing. |

|

5 |

Vertical milling machine reduces the tool life. |

Horizontal Milling Machines help to increase the tool life. |

|

6 |

This machine requires a smaller area. |

A horizontal milling machine requires a bit larger area. |

|

7 |

In the vertical milling machine, we don’t get proper removal of chips. |

In a horizontal milling machine, chips are removed and thrown away from the machine properly and easily. |

|

8 |

Its working capacity is low. |

Its working capacity is hight. It can do the work of 3 - 4 vertical milling machines easily. |

|

9 |

This type of machine is less powerful and are lighter in weight. |

It is heavier in weight and more powerful than vertical milling machines. |

|

10 |

It is the ideal solution for quick milling jobs. |

It is perfect for high-cheap removal work, high-horsepower and a heavy-duty. |

In short, vertical milling machines and horizontal milling machines have their own characteristics. Vertical milling machine is cheaper and suitable for quick milling jobs. However, horizontal milling machine is much more expensive and widely used for high-cheap removal work, high-horsepower and a heavy-duty.