How to Select the Right Milling Cutter ?

What is milling cutter?

A milling cutter is a rotating cutter with one or more cutter teeth used for milling (a mechanical processing method using a milling cutter as a tool for processing the surface of an object). When working, each cutter tooth intermittently cuts the residual of the workpiece in sequence. The milling cutter is mainly used for processing planes, steps, grooves, forming surfaces and cutting off workpieces on a milling machine. This article mainly introduces some principles and precautions for tool selection.

When choosing a milling cutter, take the following 3 points into consideration.

1. Is the milling cutter used on a CNC machining center or an ordinary milling machine?

2. The material and hardness of the milling cutters.

3. Milling cutter specifications, such as: blade length, full length, blade diameter, shank diameter, etc.

If it is used on a CNC machining center, it should be selected from solid carbide, and white steel can be used on ordinary milling machines.

White steel milling cutters are softer than carbide milling cutters. High-speed steel cutters are cheap and have good toughness, but the strength is not high, it is easy to make the knife, and the wear resistance and thermal hardness are relatively poor. The thermal hardness of the high-speed steel milling cutter is about 600 degrees, and the hardness is about 65HRC. Obviously when using white steel milling In the case of hard materials, it is easy to burn the knife if the coolant is not in place. This is one of the reasons why the thermal rigidity is not high.

Carbide milling cutters have good thermal rigidity and wear resistance, but poor impact resistance. They can be broken if you drop the blade. Carbide is a material made by powder metallurgy. The hardness can reach about 90HRA. The thermal properties can be Up to about 900-1000 degrees. Therefore, white steel is suitable for ordinary milling machines, and alloy milling cutters are used for CNC machining centers.

In addition, there are some principles for tool selection. Mastering these can save you a lot of costs.

Selection of milling cutter diameter

The choice of milling cutter diameter varies greatly depending on the product and production batch. The choice of cutter diameter mainly depends on the specifications of the equipment and the processing size of the workpiece.

1. Plane cutter. When selecting the diameter of the plane milling cutter, the power of the cutter should be considered within the power range of the machine tool, and the diameter of the spindle of the machine tool can also be used as the basis for selection. The diameter of the plane milling cutter can be selected according to D = 1.5d (d is the diameter of the main shaft). In mass production, the tool diameter can also be selected according to 1.6 times the cutting width of the workpiece.

2. End mill. The choice of the diameter of the end mill should mainly consider the requirements of the workpiece processing size, and ensure that the power required by the tool is within the rated power range of the machine tool. If it is a small-diameter end mill, the main consideration should be whether the maximum speed of the machine tool can reach the minimum cutting speed of the tool (60m/min).

3. Groove cutter. The diameter and width of the groove milling cutter should be selected according to the size of the workpiece to be processed, and the cutting power should be within the power range allowed by the machine tool.

Selection of milling cutter blades

1. For fine milling, it is best to use a grinding blade. This kind of insert has better dimensional accuracy, so the positioning accuracy of the cutting edge in milling is higher, and better machining accuracy and surface roughness can be obtained. In addition, the development trend of grinding milling inserts used in finishing is to grind out chip flutes to form large positive rake angle cutting edges, allowing the insert to cut at small feeds and small depths of cut. But for the carbide blades without sharp rake angle, when using small feed and small cutting depth, the tool tip will rub the workpiece and the tool life is short.

2. In some processing occasions, it is more appropriate to choose a pressing blade, and sometimes it is necessary to choose a grinding blade. For roughing, it is better to use pressed blades, which can reduce the processing cost. The dimensional accuracy and sharpness of the pressed blade are worse than the ground blade, but the edge strength of the pressed blade is better, it is impact resistant during roughing and can withstand a larger depth of cut and feed. Pressed blades sometimes have chip flutes on the rake surface, which can reduce the cutting force, and at the same time reduce the friction with the workpiece and chips, reducing the power requirements.

3. However, the surface of the pressed blade is not as tight as that of the grinding blade, and the dimensional accuracy is poor. The height of each tip on the cutter body of the milling cutter differs greatly. Because the pressing blade is cheap, it is widely used in production.

4. The sharpened blade with large rake angle can be used to mill sticky materials (such as stainless steel). Through the cutting effect of the sharp blade, the friction between the blade and the material of the workpiece is reduced, and the chips can leave the front of the blade faster.

5. As another combination, the pressing blade can be installed in the blade seat of most milling cutters, and then a polished scraping blade is configured. The squeegee blade removes rough machining marks, and can obtain a better surface roughness than just pressing the blade. Moreover, the use of a squeegee blade can reduce cycle time and cost. Scraping technology is an advanced technology, which has been widely used in the fields of turning, grooving and cutting and drilling.

Selection of cutter body

The price of imported milling cutters is relatively expensive. The price of a face milling cutter body with a diameter of 100mm may exceed 600 US dollars, so it should be carefully selected to meet the specific processing needs.

1. First of all, when choosing a milling cutter, we must consider its number of teeth. For example, a coarse tooth milling cutter with a diameter of 100 mm has only 6 teeth, while a dense tooth milling cutter with a diameter of 100 mm can have 8 teeth. The size of the tooth pitch will determine the number of cutting teeth that are involved in cutting at the same time during milling, which affects the stability of the cutting and the requirements for the cutting rate of the machine tool. Each milling cutter manufacturer has its own series of coarse and dense-toothed face milling cutters.

2. Coarse tooth milling cutters are mostly used for rough machining because it has a larger chip flute. If the chip pocket is not large enough, it will cause difficulty in chip curling or increase the friction between the chip and the cutter body and workpiece. At the same feed rate, the cutting load of each tooth of the coarse-tooth cutter is larger than that of the dense-tooth cutter.

3. During fine milling, the cutting depth is shallow, generally 0.25-0.64mm, the cutting load per tooth is small (about 0.05-0.15mm), the required power is not large, you can choose a dense-tooth milling cutter, and you can choose a larger one Feed rate. Since the metal removal rate is always limited in fine milling, it may be fine if the chip flute of the compact tooth cutter is smaller.

4. For the spindle with larger taper hole size and better rigidity, it can also be rough milled with a dense tooth milling cutter. Since dense teeth milling cutters have more teeth involved in cutting at the same time, when using a larger cutting depth (1.27-5mm), it is necessary to pay attention to whether the power and rigidity of the machine tool are sufficient, and whether the chip cutter flute is large enough. The chip evacuation situation needs to be verified by experiment. If there is a problem with chip evacuation, the cutting amount should be adjusted in time.

5. When performing heavy-duty rough milling, excessive cutting force can cause the machine tool with poor rigidity to vibrate. This chattering can cause chipping of carbide inserts, which shortens tool life. The use of coarse-tooth milling cutters can reduce the power requirements of the machine tool. Therefore, when the specification of the spindle hole is small, it can be effectively milled with a coarse-tooth cutter.

Which milling cutter should be chosen? a left-handed cutter or a right-handed cutter?

If the end mills are easily distinguished, they can be divided into two categories: left-handed and right-handed. Many people still have no concept of left-handed and right-handed.

Right-hand milling cutter

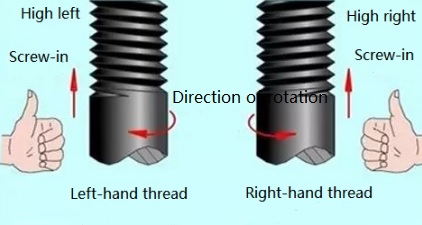

First, determine whether the tool is left-handed or right-handed according to the following method. Facing the milling cutter placed vertically, if the blade groove rises from the lower left to the upper right, this is right-handed; if the blade groove rises from the lower right to the upper left, this is left-handed. The right hand can also be ruled by the right hand. The curved four fingers are the rotation direction, and the prying thumb is the right direction. The spiral flute plays the role of chip holding, and is also the part that constitutes the front angle and front of the milling cutter.

Left-hand milling cutter

The left-handed milling cutter is generally a tool that is only selected under the requirement of high-precision machining. The left-handed milling cutter is generally used in the processing of mobile phone keys, membrane switch panels, LCD panels, acrylic lenses and other finishing. But there are some high requirements, especially some mobile phone buttons or the production and processing of electrical panels, high precision and high finish requirements are also high, you must choose the bottom row of cutting, turn left, so as to avoid whitening of the blade, processing Phenomenon such as cutouts.

In the entire manufacturing industry, the tools used for processing are usually right-handed tools. For the milling cutter, the groove of the blade body determines the direction of the chip discharge during milling. If you are making precision parts, it is recommended to use a left-handed tool. The left-handed tool requires special advantages for machining special parts.