A Complete Guide to Lathe Machine, Lathe Type, Lathe Operations and Turning Cutting Tool

Lathe Definition

A lathe is a machine for shaping wood, metal, or other material by means of a rotating drive which turns the piece being worked on against changeable cutting tools.

Types of Lathe

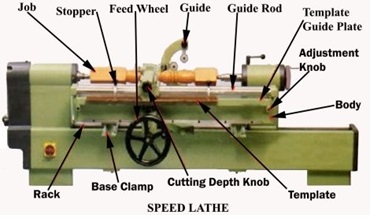

1. Speed Lathe Machine

Speed lathe machine has less depth of cut. The name speed lathe has been given because of the very high speed of the headstock spindle.

2. Engine Lathe Machine

The engine lathe is the most widely using in the lathe machine. These machines are driven by the gear mechanism or pulley mechanism. The name engine lathe is given because of the earlier lathe were driven by steam engines.

3. Bench lathe

These types of lathe machines are small in size and use for very small precision work. Bench lathe machines are mounted on the bench. It has all the similar parts of engine lathe and speed lathe. Bench lathe machine performs almost all the operations of engine lathe and speed lathe its only difference being in the size.

4. Toolroom Lathe Machine

The toolroom lathe machine is the same as that of engine lathe but provides a wide range of speed. The spindle speed range is from very low to a quite high speed up to 2500rpm.

Toolroom Lathe is expensive as compared to the engine lathe. It is mainly using in grindings, working on the tool, dies gauges, and in machining work where is accuracy is needed.

5. Capstan Lathe and Turret Lathe

These lathe machines are the development of the engine lathe. These machines provided by hexagonal turret head instead of the tailstock. It also consists of three tool post.

The main advantage is that different operations and parts can produce in very less amount of time. And also without changing the tool the quantity and quality are high.

6. Special purpose lathe machines

In this lathe, special operations are performed such as drilling, grinding, reaming, boring, etc.

7. Automatic Lathe

In Automatic Lathe, all the work is done automatically. These are the high-speed heavy-duty, production lathes. In these types of lathe machines once the tool is set it performs all the operations automatically to finish the job.

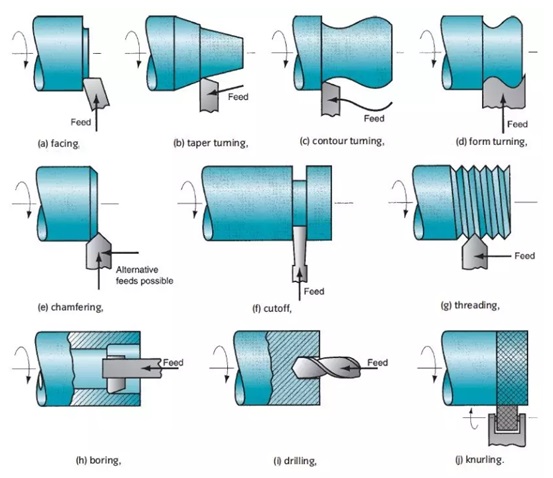

Types of Lathe Operations or Lathe Machine operations

The general lathe operations or lathe machine operations are grooving, turning, cutting, sanding and etc.

(a) Turning

(b) Facing

(c) Parting off

(d) Knurling

(e) Thread cutting

(f) Grooving

(g) Drilling

(h) Boring

(i) Reaming

Turning

The definition of turning is that it remove material from the outside diameter. There are 3 types of turning which are given below :

(a) Plain turning

(b) Stepped turning.

(c) Taper turning.

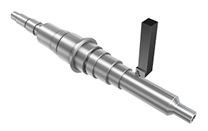

Plain Turning and Stepped Turning

In plain turning, the workpiece is turned straight throughout the entire length when it is made to rotate about the lathe axis, and the cutting tool is fed along the lathe axis. The plain or straight turning produces a cylindrical surface after machining.

In stepped turning, the workpiece is turned in such a way that throughout the turning length it forms the steps of different diameters.

Taper Turning

Turning the shaft or remove the layer of material in a certain angle.

Facing

It is the machining of the ends of a workpiece to make the ends smooth.

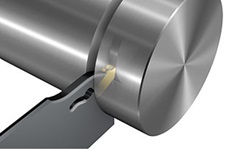

Parting Off

This operation cut the work-metal into two parts by using parting off tool.

Knurling

It is the process of producing a rough surface of embossing a diamond-shaped pattern on a smooth surface of a cylindrical job.

Thread Cutting

In thread cutting operation, there is a certain ratio of motion between the travel of tool and the rotation of the spindle. This ratio is directly affected by the lead screw which is attached to the lathe spindle through gears.

Grooving

Usually, grooves are cut on a cylindrical surface in narrow shape by means of a grooving tool. The cutting edge of the grooving tool is kept narrow.

Drilling

For making a standard size of the hole in a workpiece by means of a drill is known as drilling operation. For this operation, the drill is held in tailstock spindle.

Boring

Boring is the operation of enlarging a drilled hole by means of a boring tool. The boring tool is fitted on a boring bar which is held in tailstock spindle.

Reaming

It is the operation of finishing a drilled hole to an accurate dimension with the help of reamer as a tool. The reamer is held on the tailstock spindle.

Lathe Cutting Tools

There are several lathe cutting tools that help in cutting with the lathe machine.

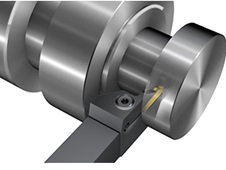

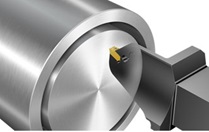

1. External turning Cutting Tools

2. Internal turning Cutting Tools

3. Parting off tool

4. External grooving tools

5. Internal grooving tools

6. Face grooving tools

7. Profiling tools

8. Thread turning tools

Summary

This article introduces the definition of Lathe Machine, Lathe Type, Lathe Operations, and Lathe Cutting Tools.