Milling VS Grinding

Milling and grinding are two common machining processes. This article share the knowlege of Milling VS Grinding. They both involve the removal of material from a workpiece, and they both support a wide variety of materials. Whether a workpiece is made of iron, aluminum, steel, copper or any other metal or alloy, it can probably be manipulated via milling or grinding. Milling and grinding are not the same, however. They each work in a different way.

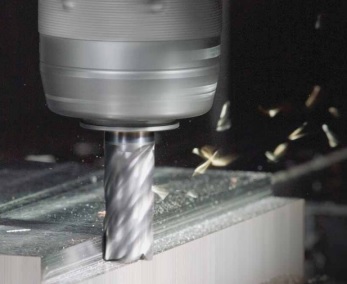

Milling VS Grinding Question 1: What is Milling?

Milling is a machining process that involves the use of a milling machine to remove material from a workpiece. Milling machines feature cutting blades that rotate while they press against the workpiece. The workpiece is secured in place so that it doesn't rotate or otherwise rotate. During operation, though, the milling machine will press a rotating cutting tool against the stationary workpiece. As the cutting tool moves across the workpiece, it scraps off material, resulting in a smaller size.

Milling VS Grinding Question 2: How is the Accuracy of Milling Machine?

A. Vertical machining center:

Flatness: 0.025/300mm, roughness: 1.6Ra/μm.

B. Longmen machining center:

Flatness: 0.025/300mm, roughness: 2.5Ra/μm.

The above processing accuracy is only a relative reference value, and does not mean that all milling machines are in line. Many milling machine equipment has a certain amount of up and down floating according to the specific requirements of the manufacturer and the specific conditions of assembly, but no matter how large this floating amount is, it's processing The accuracy value must meet the requirements of the national standard for this type of equipment. If the processing accuracy requirements of the equipment in the purchase do not meet the requirements of the national standard, the purchaser has the right to refuse acceptance and payment.

Milling VS Grinding Questions 3: What is Grinding?

Grinding, on the other hand, is a machining process that involves the use of a disc-shaped grinding wheel to remove material from a workpiece. There are several types of grinding wheels, some of which include grindstones, angle grinders, die grinders, and specialized grinding machines. Regardless of the grinding wheel, though, all grinding processes use abrasive particles to “grind” away material from a workpiece’s surface.

When a workpiece is exposed to a grinding wheel, some of its material will rub off. With that said, grinding is often used to remove material from workpieces as well as polish workpieces. If a workpiece has a coarse surface, grinding can make it smoother. The abrasive particles on the grinding wheel will smooth and, therefore, polish the workpiece’s surface.

Milling VS Grinding Question 4: Accuracy of Grinding Machine

A. Processing accuracy of cylindrical grinder:

Roundness and cylindricity: 0.003mm, surface roughness: 0.32Ra/μm.

B. Processing accuracy of surface grinder:

Parallelism: 0.01/300mm, surface roughness: 0.8Ra/μm.

From the above processing accuracy, we can clearly see that, compared with the milling machine, the grinding machine can achieve higher behavior tolerance accuracy and surface roughness, so in many parts, grinding machines are widely and commonly used in finishing processes.

Summary

Milling and Grinding have different function. So choose the suitable process can help you to make spare parts more fast, economic and reasonable. Milling Vs Grinding, which is better? It's all dependent on your needs.