What is Precision Machining?

Precision machining is a process of precision manufacturing. It’s tasks can be divided into precision turning, precision milling, and precision boring. Precision machining focuses on creating parts or objects by subtracting materials, rather than adding materials to create the correct shape.

What is precision machining?

Precision machining is defined as the use of tools, procedures, engineering personnel or equipment to process parts with high precision. The true art of precision machining comes from the combination of computer-controlled design and man-made engineering design to create unique functions and highly controlled outputs and functions. Precision machining is very important for manufacturing tools and parts in a precise and stable manner, and can be repeated, with consistency, accuracy and durability.

What is precision machining used for?

Precision machining is a subtractive process used in situations where materials need to be removed from raw materials to make a finished product. Precision machining can be used to create a wide variety of products, projects, and parts for various objects and materials. These parts usually require tight tolerance changes between nominal dimensions and parts, which means that there is not much room for error in part production. Repeatability and well-controlled tolerances are the hallmarks of precision machining.

Components designed to maintain a very small tolerance range and high durability, parts and finished products are common driving forces that are essential for the use of precision machining. For example, parts that need to work together as machine parts may need to be always aligned within a certain range of 0.01 mm to 0.05 mm. Sophisticated engineering and machining help ensure that not only can these parts be manufactured accurately, but can also be produced with this precision over and over again.

How does precision machining work?

Precision machining is a subtractive process in which custom software, engineering tools, and process steps are used with raw materials (such as plastic, ceramic, metal, or composite materials) to create the fine products required. Precision machining generally follows the instructions given by computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. These procedures and blueprints enhance the ability to meet tight tolerances.

What tools and materials are used for precision machining?

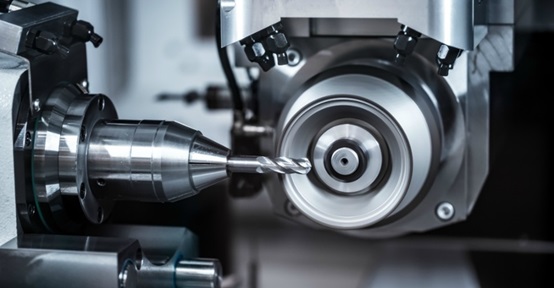

Precision machining can be used for a variety of raw materials, including plastics, ceramics, metals, composite materials, steel, bronze, graphite and glass. For precise cutting and complex removal of raw materials, a variety of equipment can be used. These tools depend on the raw materials. Commonly used equipment includes milling machines, lathes, EDM machines (aka EDM), saws and grinders.

What is precision machining capability?

The ability of precision machining refers to the ability of machinery and technology provided by precision machining providers to create parts accurately and precisely according to strict specifications. The precision machining capability refers to the accuracy with which a supplier can manufacture parts, objects or components, regardless of size, complexity, or small and precise. Due to the extremely high accuracy, many parts need to be manufactured, so this accuracy must be maintained within a range of different object sizes and shapes. The ability of precision machining is the ability to achieve this goal.

Equipment for determining accuracy capability

The tools and machines used to create precise components must be of high quality and be able to operate to very strict specifications. There are multiple tools available for different aspects of precision machining. These tools are usually controlled by CNC or computer numerical control. This type of control converts very accurate designs produced by computer-aided design (CAD) into numbers, which are used as coordinates to control the precision machining process. Regardless of the nature of the manufactured parts, this helps ensure accuracy and adherence to strict tolerances.

Precision machining tasks

In general, precision machining tasks can be divided into milling, turning and boring.

Summary

This article introduce precision machining definition, tools and tasks.