What are the different tool holders for CNC machining centers, do you know?

Nowadays, CNC machine tools are widely used in factories. These machine tools and tools used come from all over the world, with different models and standards. Today I will talk to you about the knowledge of machining center tool holders.

The tool holder is the connecting body of the machine tool and the tool. The tool holder is a key link that affects the concentricity and dynamic balance. It must not be treated as a general component. Concentricity can determine whether the cutting amount of each cutting edge part of the tool is uniform when the tool rotates one circle; dynamic imbalance will produce periodic vibration when the spindle rotates.

01 According to spindle taper

According to the taper of the spindle of the machining center, it is usually divided into two categories, the SK universal tool holder with a taper of 7:24 and the HSK vacuum tool holder with a taper of 1:10

SK universal tool holder with a taper of 7:24

7:24 means that the taper of the tool handle is 7:24, which is a single taper surface positioning, and the taper handle is longer. The cone surface plays two important roles at the same time, namely the precise positioning of the tool holder relative to the spindle and the realization of tool holder clamping.

Advantage:

It is not self-locking, which can realize quick loading and unloading of tools; the manufacturing tool holder only needs to process the taper angle to high precision to ensure the accuracy of the connection, so the cost of the tool holder is relatively low.

Disadvantages:

The taper hole at the front end of the spindle will expand during high-speed rotation. The amount of expansion increases with the increase in the radius of rotation and the speed, and the rigidity of the taper connection will decrease. Under the action of the pull rod, the axial displacement of the tool holder will also be changes happened. The radial dimension of the tool holder will change every time the tool is changed, and there is a problem of unstable repeat positioning accuracy.

There are usually five standards and specifications for universal tool holders with a taper of 7:24:

1. International Standard IS0 7388/1 (referred to as IV or IT)

2. Japanese standard MAS BT (abbreviated as BT)

3. German standard DIN 2080 type (abbreviated as NT or ST)

4. American Standard ANSI/ASME (CAT for short)

5. DIN 69871 type (abbreviated as JT, DIN, DAT or DV)

Tightening method:

The NT type tool holder is tightened by the tie rod on the traditional machine tool, which is also called ST in China; the other four tool holders are tightened by the pull nail at the tail of the tool holder on the machining center.

Versatility:

1) At present, the most widely used tool holders in China are DIN 69871 type (ie JT) and Japan MAS BT type tool holders;

2) DIN 69871 type tool holder can also be installed on ANSI/ASME spindle taper hole machine;

3) International standard IS0 7388/1 type tool holder can also be installed on DIN 69871 type, ANSI/ASME spindle taper hole machine tool, so in terms of versatility, IS0 7388/1 type tool holder is the best.

HSK vacuum tool holder with a taper of 1:10

HSK vacuum tool holders rely on the elastic deformation of the tool holder, not only the 1:10 tapered surface of the tool holder is in contact with the 1:10 tapered surface of the spindle hole of the machine tool, but also the flange surface of the tool holder is in close contact with the spindle surface. The surface contact system is superior to the 7:24 universal tool holder in terms of high-speed machining, connection rigidity and coincidence accuracy.

HSK vacuum tool holder can improve the rigidity and stability of the system and the product accuracy during high-speed machining, and shorten the time of tool replacement. It plays an important role in high-speed machining. It is suitable for the spindle speed of the machine tool to reach 60,000 rpm. HSK tool systems are being widely used in manufacturing industries such as aerospace, automobiles, and precision molds.

HSK tool holders are available in A-type, B-type, C-type, D-type, E-type, F-type and other specifications. Among them, A-type, E-type and F-type are commonly used in machining centers (automatic tool change).

The biggest difference between Type A and Type E:

1. Type A has a transmission groove but Type E does not. So relatively speaking, A-type transfer torque is relatively large, and it is relatively capable of some heavy cutting. The torque transmitted by the E-type is relatively small and can only perform some light cutting.

2. In addition to the transmission groove on the A-type tool holder, there are manual fixing holes and direction grooves, so the balance is relatively poor. The E type does not, so the E type is more suitable for high-speed processing. The mechanism of E-type and F-type is exactly the same. The difference between them is that for the same-named E-type and F-type handles (such as E63 and F63), the taper of the F-type handle is one size smaller. That is to say, the flange diameters of E63 and F63 are both φ63, but the size of the cone of F63 is only the same as that of E50. So compared with E63, the speed of F63 will be faster (small spindle bearing).

02 According to the type of tool holder

Collet chuck

It is mainly used for clamping straight shank knives and tools such as drills, milling cutters, and taps. The elastic deformation of the circlip is 1mm, and the clamping range is 0.5~32mm in diameter.

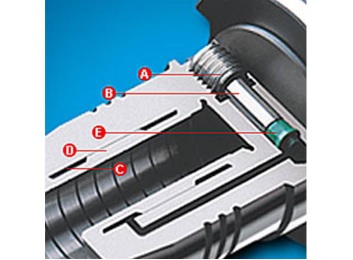

Hydraulic chuck

A- For the locking screw, use an Allen key to tighten the locking screw;

B- Lock the piston and press the hydraulic medium into the expansion chamber;

C- Expansion chamber, pressure generated by liquid squeezing;

D-Thin expansion bushing, which makes the tool clamping rod center positioned and evenly enveloped during the locking process

E- special seals to ensure ideal sealing and long service life.

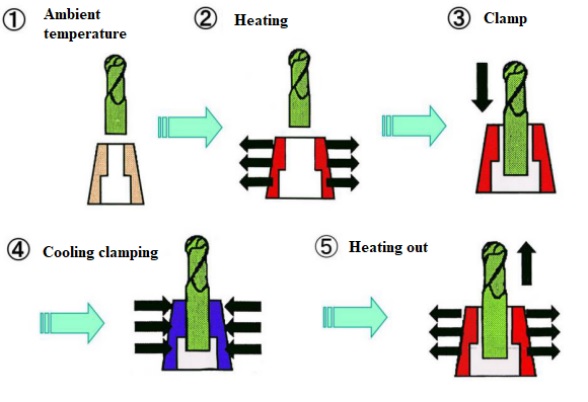

Heated knife handle

Application of induction heating technology to heat the tool clamping part on the tool holder, so that its diameter will expand, and then put the cold tool holder into the hot tool holder. The heating tool holder has large clamping force and good dynamic balance, which is suitable for high-speed processing. The repositioning accuracy is high, generally within 2μm, and the radial runout is within 5μm; the anti-fouling ability is good, and the anti-interference ability during processing is good. However, each type of tool holder is only suitable for installing a tool with one shank diameter, and a set of heating equipment is required.

The principle of heat shrinkable tool holder clamping:

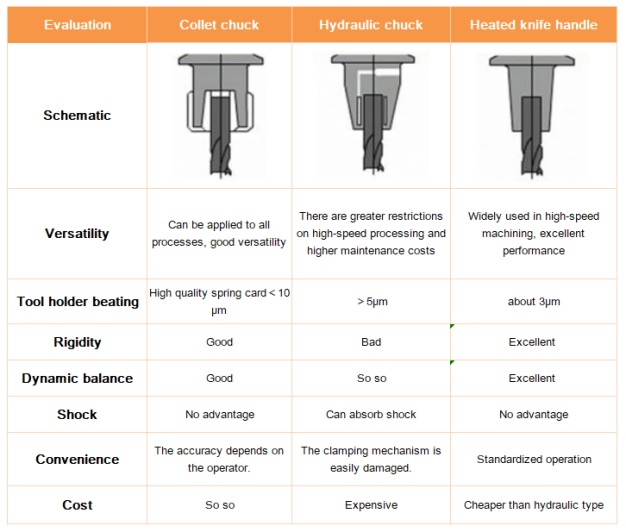

Comprehensive evaluation and comparison of tool holders:

Other types of handles