What should be paid attention to after the CNC machine tool processing is completed?

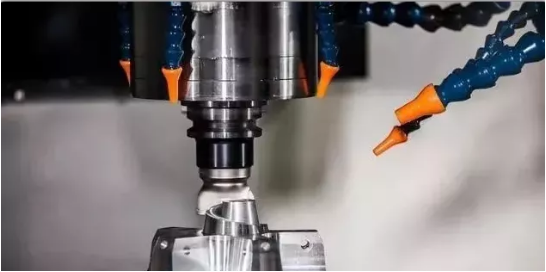

Numerical control machining refers to the machining of parts on CNC machine tools, and uses digital information to control the displacement of parts and tools. It is to solve the problems of variable parts, small batches, complex shapes, and high precision, and to achieve high efficiency and automation Effective way of processing.

The process regulations of CNC machine tool processing and traditional machine tool processing are generally the same, but because CNC is a one-time clamping and continuous automatic processing completes all turning processes, some things need to be paid attention to after the CNC machine tool processing is completed.

Matters needing attention after processing:

1. Remove chips, wipe the machine tool, use the machine tool and keep the environment clean.

2. Pay attention to check or replace the oil wiper plate on the machine tool rail that is damaged by grinding.

3. Check the status of lubricating oil and coolant, add or replace in time.

4. Turn off the power supply and the main power supply on the machine operation panel in turn.

5. The machine tool should follow the principle of zero return first (except for special requirements), manual, jog, and automatic. The operation of the machine tool should follow the principle of low speed, medium speed and high speed first, and the running time of low speed and medium speed should not be less than 2-3 minutes. When it is determined that there is no abnormal situation, the work can be started.

6. It is strictly forbidden to hit, correct and correct the workpiece on the chuck or between the centers. The workpiece and the tool must be clamped before proceeding to the next step.

7. The operator must stop the machine when changing tools, workpieces, adjusting workpieces or leaving the machine tool while working.

8. The insurance and safety protection devices on the machine tool must not be disassembled or moved arbitrarily by the operator.

9. Before the machine tool starts processing, the program verification method must be used to check whether the program used is similar to the processed part. After confirming that it is correct, the safety shield can be managed and the machine tool can be started for parts processing.

10. Machine tool accessories, measuring tools, and cutting tools should be properly kept, kept intact and in good condition, and compensated for loss or damage.

11. After the training, the machine should be cleaned and kept clean, the tailstock and carriage should be moved to the end of the bed, and the power supply of the machine should be cut off.

12. When the machine tool fails or is abnormal during work, it should be shut down immediately to protect the site, and at the same time immediately report to the site to be responsible.

13. The operator is strictly prohibited to modify the machine parameters. If necessary, the device administrator must be notified, and the device administrator must modify it.

14. Understand the technical requirements of the part drawing, and check the size and shape of the blank for defects. Choose a reasonable method of installing parts.

15. Choose the CNC turning tools correctly, and ensure that the installation parts and tools are accurate and firm.

16. Understand and master the control and operation panel of the CNC machine tool and its operating essentials, input the program accurately into the system, and simulate inspection and room cutting, and do various preparations before processing.

17. If you find that the lathe is running abnormally or malfunctions during processing, you must stop and check immediately and report to the instructor to avoid danger.