What is Face Milling? 10 Tips You Should Know abount Face Milling

What is Face Milling? Face milling definition

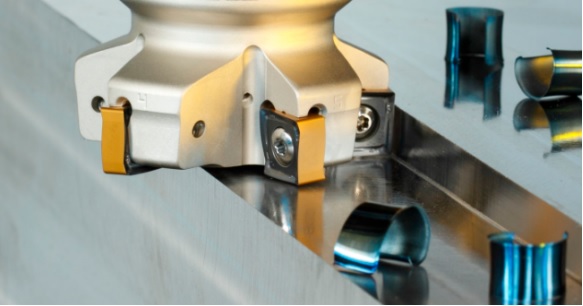

What is face milling? Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

When you’re looking to get a precisely-flat surface or you want a finish that really makes your part shine, the process of face milling can help you get there.

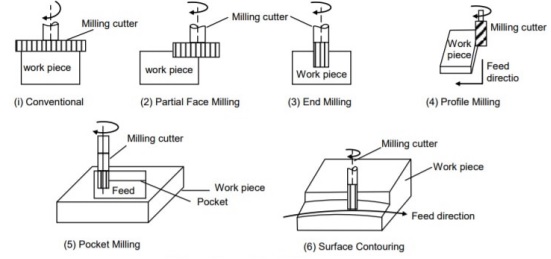

Different 6 Types Of Face Milling Operations

Depending upon the relative geometry of workpiece and milling cutter face milling is different types as described below.

Conventional Face Milling: In this case diameter of the milling cutter is greater than the width of the workpiece. The milling cutter remains overhanging on both sides of the workpiece.

Partial Face Milling: In this case, the milling cutter overhangs on the workpiece on one side only.

End milling: In case of end milling thin (low diameter) cutter is used as compared to workpiece width. It is used to make a slot in the workpiece.

Profile Milling: This is just like end milling in which the outer side periphery of a flat part is machined (milled).

Pocket Milling: This is a selective portion milling on the flat surface of the workpiece used to make shallow packets there.

Surface Contouring: In this operation a ball nose cutter if feedback and forth across the workpiece along a curvilinear path at short intervals. This creates the required contours on the surface of the workpiece. This operation is used to make contours of molds and dies and this time the operation is named as die sinking.

10 Tips You Should Know for Face Milling During CNC Machining

1. If you’re going to be cutting things like steel, we recommend sticking to our shell mill. The 38 mm shell mill can do the operation a bit faster in harder metals, but the fly cutter with the proper inserts can also handle such operations, it’ll be a bit slower, but it can handle the cuts and still give you a nice finish.

2. In softer materials, like aluminum, the fly cutter will still give you fantastic results.

3. Take into account your tool stability and the horsepower in your spindle. With all those teeth and a smaller spindle, a million-tooth shell mill is going to get bogged down really fast.

4. No matter what material you’re cutting, it’s usually recommended that you position the cutter off-center from your workpiece when face milling. This provides the thinnest chip at the cutter’s exit, which leads to a cleaner cut and finer finish. To this end, frequent entering and exiting of the workpiece should be avoided – it can create some stresses on the cutting edge that may result in dwell and chatter tendencies. So, keep your tool paths on your workpiece as much as possible.

5. For the same reason, you should also try to avoid face milling over holes or slots, because these edges cause multiple cut entries and exits. If you find it necessary to cut over surfaces with these sorts of interruptions, you can help ease the stress on your cutter by reducing the feed rate.

6. Face milling operations are a great way to remove some material and get a nice flat surface, but the real joy comes when you get to see that surface finish. Rest assured, if you aren’t already addicted to facing, you will be when you see that shine.

7. Keep your tool paths on your face milling part as much as possible.

8. Avoid face milling over holes or slots.

9. The workpiece should be fed against the milling cutter so that the pressure of the cut is downward, thereby holding the piece against the table.

10. When setting the depth of cut, the part should be brought up to touch the revolving cutter.

Summary

This article explain what is face milling, face milling definition, 10 tips when you do on face milling.