Turning definition, Milling definition, What is Turning

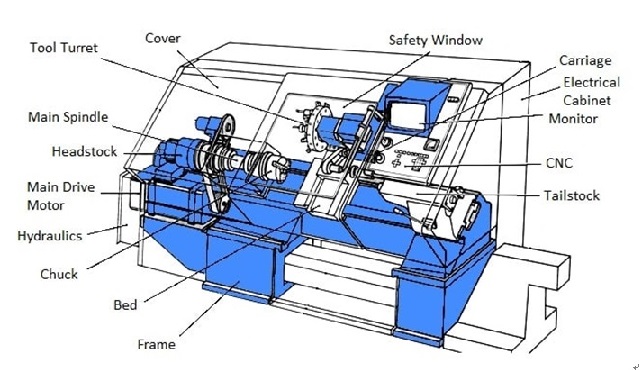

The lathe is used to process the parts of the rotary body, and the parts are clamped on the spindle of the machine tool through the three-clamp chuck, and rotated at a high speed, and then the cutter is used to follow the busbar of the rotary body to cut out the appearance of the product. The lathe can also be machined with internal holes, threads, bites, etc., the latter two being processed at low speed. CNC lathes can be used to machine complex rotary shapes.

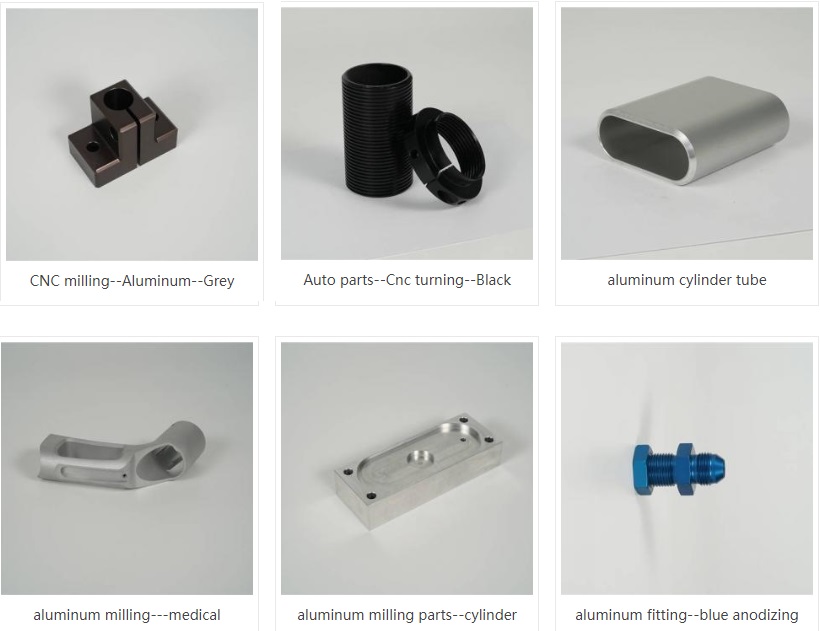

The milling machine fixes the blank and uses a high-speed rotating cutter to cut the blank and cut out the desired shape and features. Conventional milling is used more for simple shapes/features such as milling contours and grooves. CNC milling machines allow for the machining of complex shapes and features.

The milling and boring machining center can perform three-axis or multi-axis milling and machining for machining, molds, inspection tools, tire tools, thin-walled complex curved surfaces, artificial prostheses, and blades.

The

lathe is moving the workpiece and the tool does not move. The milling machine

is a workpiece that does not move and the tool moves.

What is Turning? What is Lathe? Turning Definition

We are proud to offer you our CNC Lathe Machining services that we are ready to provide for your precision CNC Turned Parts that will meet and exceed your requirements. Our state-of-the-art CNC Turning equipment holds close tolerances and delivers smooth finishes.

Our CNC Turning services are capable of Turning parts measuring up to 25 inches in length, meeting ultra-tight tolerances of ± 0.0002”. We could machine all kind of material , includes all types of steel, cast iron, aluminium, copper, brass, and bronze, as well as plastics such as nylon, acetal, PTFE, and fibreglass.All these material are RoHS,the material reports could be supplied upon requested.We machine from castings, bar stock, plates and more. We can work in standard or metric dimensioning depending on your needs.

With the ability to handle all of our clients’ unique manufacturing needs, from low- to high-volume production and prototyping,DESHENGRUI Machinery offers top class CNC Turning services for our customers.

Desheng Precision provide lathing, CNC machining,Machining CNC, CNC Turning, CNC lathe, CNC milling service.

Service Available:

|

CNC Milling |

CNC Turning |

|

|

CNC machining services |

Precision CNC milling |

CNC turned components |

|

Aerospace CNC machining |

Custom CNC milling |

Brass turned components |

|

5 axis CNC machining |

CNC milling services |

CNC Turning services |

|

Swiss precision machining |

CNC milling parts |

CNC Turning parts |

|

CNC prototype machining |

CNC machined parts |

Aluminum CNC Turning parts |

|

Machine shop services |

CNC machined services |

Steel CNC Turning |

|

CNC machining parts |

Precision machined parts |

Plastic machining |

|

CNC company |

Aluminum machining |

Metal machining |

|

CNC machine shop |

Steel machining |

Machining aluminum |

Material Available:

|

Stainless Steel |

SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000, C12000, C12000, C26000, C51000 etc. |

|

Aluminium |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

|

Plastic |

ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek.Carbon Fiber |

|

Wood |

OAK, Rosewood, Rubber Wood, Beech, Cherry |

Surface Finish:

|

Aluminum parts |

Clear Anodized |

|

Stainless Steel parts |

Polishing |

|

Steel |

Zinc plating |

|

Plastic |

Painting |

What Are The Advantages of Working With Us?

Our Capacity:

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC Milling |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

CNC Machining |

1000 * 1000 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS, STP, X_T , DXF, DWG , Pro/E, PDF |

|

|

Test Equipment |

Projector, CMM, Altimeter, Micrometer, Thread Gauge, Calipers, Pin Gauge etc. |

|

Our Fast Service:

|

Quotation Speed |

We are aiming at to quote the parts in one working date. |

|

Samples Delivery |

It will take us 7 days to make the samples. |

|

Mass production delivery |

Our mass production time is about 15-20 days according to different quantity. |

|

shipping |

Sometimes we use DHL/FedEx/UPS/TNT to make the air ship; normally our parts are shipped by sea. |

|

Tooling time |

For the stamping parts, the tooling time is 20 days; for injection mold, it will need about 30 days. |

7 tips to operate the CNC Lathe Machines

CNC (computer numerical control) tools such as lathes have become a vital part of manufacturing in a wide variety of industries. With a CNC lathe, you can easily produce complex parts that would be very difficult to machine on a manual lathe. A CNC lathe still requires significant skill to operate properly, but you can learn basic CNC machining techniques with the right training and practice. Below are some tips for newer machines.

Tip 1.Load the part program into the lathe if it is not already there. On newer machines, use a USB drive to transfer programs from a computer to the machine. With old machines, you may need to use a serial connection to the computer or even a 3.5-inch floppy disk.

Tip 2.Load the workpiece into the lathe. Make sure the chuck or collet has a tight grip on the workpiece.

Tip 3.Load the necessary tools into the lathe. The tools you will need for a given program, as well as the turret slots in which they should be placed, will have been determined at the time the program was written. If you will be using a program you did not write, consult the programmer if you have any questions about which tools to use.

Tip 4.Turn on the coolant pump and move the nozzle so the coolant stream is hitting the tip of the tool. Repeat this step for each tool.

Tip 5.Set the tool offsets. Slowly bring each tool toward the tool setter on the lathe until you hear a beep. Record the tool's position in the tool offset screen under the appropriate tool number. Repeat this procedure to set the X and Z offsets for each tool. For some programs, you will also have to record the tip radius of certain cutting tools in the tool offset screen. The tip radius should be found either marked on the tool or in the documentation for the tool.

Tip 6.Set the work offset. Rotate the turret to one of the cutting tools for which you have set the tool offset. Start the spindle and manually jog the cutter so that it faces off the end of the workpiece, leaving a smooth surface. Record the tool's position under the Z-axis work offset.

Tip 7. Run the part program. Watch the machine to make sure the program works as intended. Be ready to stop the machine immediately if something goes wrong.

If you are interested to become a CNC lather, you could try to find a job in our workshop. Currently, we have more than 35 CNC Lathe machines, our operators have more than 8 working experience in this field, we could train you. Then more and more custom CNC parts will be sold to our customers.

KUNSHAN DESHENGRUI MACHINERY CO., LTD can provide CNC Machining service, which specialized in developing, manufacturing and exporting mechanical products for many years.