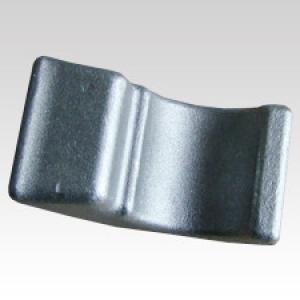

Rod End Product Description-custom aftermarket motorcycle parts

Rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint.

Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required.

A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached.

The threaded portion may be either male or female

1. Left or right hand threaded rod

2. Male or female / hollow / internal thread rod ends

3. Machining or forging rod ends

4. Surface: White Zinc, brass, Chrome, Nickle and so on

5. High precision

6. Metric and inches sizes available

7. High & Stable quality

8. OEM / Customized Service

|

Used for industries |

Automotive, Automation, Test systems, Sensors, Medical, Home appliance, Electronic , Pumps, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, etc. |

|

Material range |

Stainless Steel 303/304/316/316L, Aluminum 5052/6061/6063/7075/2027, Brass H58/H62/H70, Bronze, Steel Alloys 42CrMo/35CrMo/30Cr/20Cr/20CrMnTi/16MnCr5/20MnCr5/4140/4340, Carbon steel 20/35/45, Cold rolled sheet, Bearing steel. |

|

Process range |

CNC Machining, Precision Machining, Custom Machining, CNC PRECISON MACHINING, CNC Turning, CNC Milling, Sheet Metal Stamping, Bending, Welding, Tapping, Riveting, Wire-cutting, Die Casting, Steel Forging, Ductile iron casting, Steel Casting |

|

Surface roughness |

Ra 0.4-3.2 |

|

Machining size |

1mm -1800mm |

|

Surface treatment |

Anodize, Vacuum plating, Nickel, Zinc plating ,Powder coating, Passivation, Electrolytic polishing, Sandblasting, Brushing, Gas nitriding etc. |

|

Lead time for samples |

3-15 days |

|

Lead time for orders |

According to batch quantities |

|

MOQ |

1PC ~100k PCS |

|

SHIPPING TERMS |

T/T, LC, Paypal |

|

Packing |

Carton box or wood CASES, or per customers' requirement |

|

Forwarder |

Air Freight- Fedex, DHL, UPS, TGL, etc .or per customers' requirement |

|

Sea Freight- per customers' requirement |