INSPECTION

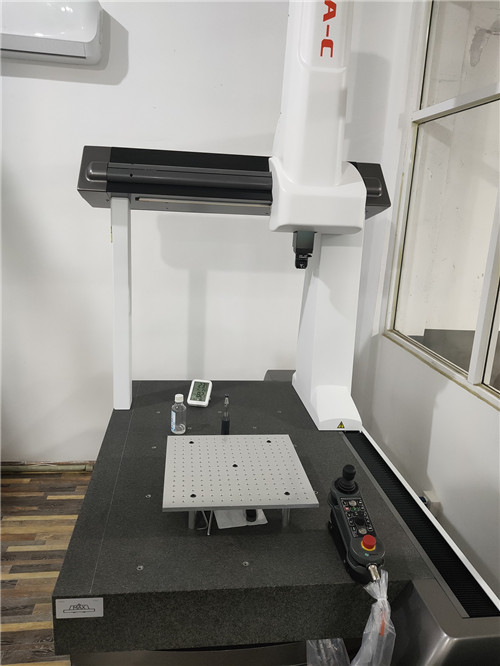

What is a CMM?

Three-coordinate measurement in coaxiality detection is a problem we often encounter in measurement work. The use of three-coordinate for coaxiality detection is not only intuitive and convenient, but the measurement accuracy of three-dimensional, 2.5-dimensional and three-coordinate is high, and Repeatability is good.

The function of the coordinate measuring machine is to quickly and accurately evaluate the dimensional data, providing the operator with useful information about the condition of the production process, which is quite different from all manual measuring devices. The object to be measured is placed in the coordinate measuring space, and the coordinate positions of the measuring points on the measured object can be obtained. According to the spatial coordinate values of the points, the geometric size, shape and position of the measured object are calculated.

Deshengrui CMM Equipment

QUALITY CONTROL

DESHENG PRECISION has a very strict quality control. We have advance inspection tools and inspect our product at Constant temperature room to ensure to reach the small tolerance.

Company Certifications

Certificate Standard: ISO 9001:2000

Issue Date: 01-Aug-2015

Expiry Date: 01-Aug-2020

Issued By: BM Trada Certification Ltd.

Materials/Components

All materials are traced from purchasing to shipping. CoC

is included in the inspection reports in each step.

Procedures/testing Details

For each project, we have a plan with three main

steps:

1. First article inspection.

2. In production inspection.

3. Pre-shipment inspection.

All inspection reports are sent to customers for

approval. All reports are submitted with COC. In order to meet clients'

requirements, DESHENG PRECISION can submit PPAP and CPK documents.

DESHENG

PRECISION uses the following inspection equipment:

1. Hardness tester.

2. Yield strength tester.

3. Impact strength tester.

4. Metallographic analyzer

5. CMM.