Brief introduction to machining cutting tools

Cutting tools are indispensable machining tools in machine building, also known as cutting tools. The cutting tool includes both tools and grinding tools. At the same time, the "CNC tool" includes some accessories such as the shank and handle in addition to the cutting blade!

According to the structure tool can be divided into:

Integral: The tool is integrated, made of a blank, and is not separated;

Welding type: connected by welding method, includes the cutter head and the cutter bar;

Machine clamping type: Machine clamp type can be divided into two types: non-indexing and indexable, usually CNC tools are machine-clamping!

Special types: such as compound tools, shock-absorbing tools, etc.

The materials used for the tool can be divided into the following:

High speed steel cutter;

Carbide tool;

Diamond cutter

Ceramic knife;

From the cutting process can be divided into:

Turning tools, such as outer circle, inner hole, thread, cutting, grooving tool, etc.;

Drilling tools, including drill bits, reamers, taps, etc.;

Boring tool

Milling tools, etc.

We should select the suitable cutting tool according to the material of the parts, which can ensure the machining life and achieve the maximum production benefit.

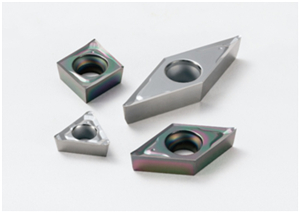

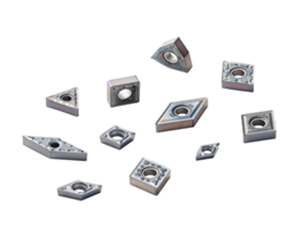

Turning tools:

Specific

applications:

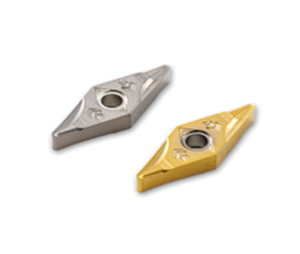

● CVD coated metal cermet for finishing, a new power to improve production efficiency! Fusion of metal cermet and CVD coating for high speed machining;

●The CVD coating material for steel processing

challenges long life and uses CVD coating to improve wear resistance. Excellent

resistance to breakage, both includes refractory resistance and chipping

resistance;

●Positive-angle inserts for aluminum machining,

chip breakers improve chip handling performance for aluminum machining. The

sharp tip is combined with the DLC coating to control burrs;

●The CVD coating material for cast iron

processing is combined with the sparkling rose gold series, which is combined

with the cast iron special chip breaker tool series to achieve the ultimate

effect;

●For difficult-to-cut materials, materials such

as heat-resistant alloys, titanium alloys, and stainless steel can be used to

suppress sudden breakage in black skin and intermittent processing, which can

achieve stable processing of difficult-to-cut materials. Excellent wear

resistance and heat resistance, and special hard alloy base materials can be

used for titanium alloy processing for long-life processing;

●The chip breaker for profiling produces high

productivity in the profiling of various shapes. High stability in profile

processing and V-groove processing where chip processing is difficult.

●The grinding chip breaker for inner diameter

machining can control the special shape of the chip removal direction. The

grinding chip breaker can be used in combination with a special tool bar to

improve the inner diameter machining problem.

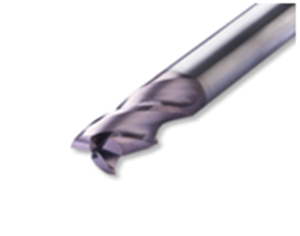

Milling tools:

Specific applications:

●The four-blade high-feed end mill achieves excellent vibration resistance and a unique cutting shape for stable cutting and discharge performance. Right angle type and rounded type can be selected according to the shape of the processing product;

●Ball end mills have long life and stable machining characteristics, and have good cutting performance for special groove shapes. Large capacity cutting enables stable cutting discharge. R tolerance ± 0.005 blade shape is for high precision machining;

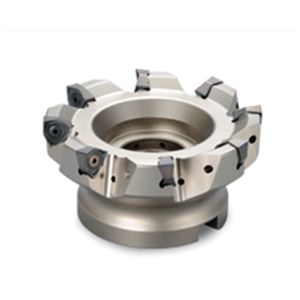

●Double-sided 6-knife size 90° milling cutter has a large forward tilting angle with smaller resistance, strong anti-vibration knife capability, and a thick gauge design blade that is more resistant to chipping. No direction need to be distinguished, not only can do face machining but also vertical machining.

●Double-sided 6-knife size 90° milling cutter has a large forward tilting angle with smaller resistance, strong anti-vibration knife capability, and a thick gauge design blade that is more resistant to chipping. No direction need to be distinguished, not only can do face machining but also vertical machining.