Benefits of Powder Coating

What is powder coating?

The process uses a powder which consists of resin and fine pigment particles, electrostatically sprayed on the metal surface. This way allows the powder particles to become charged and adhere to the metal surface while being electrically grounded, until the powder has heated up and smoothly fused with the metal in a curing oven. The powder coating process provides a durable, uniform, attractive and high-quality finish.

Benefits of Powder Coating

Since there are more benefits of powder coating, so powder coating is widely used in global market.The main Benefits of powder coating are High Efficiency, Low Cost, Different Variety,Environmental Safety, Good Quality, Easy Maintenance.

1st Benefit of Powder Coating----Efficiency

Because of the electromagnetic energy used to apply the powder to parts, there’s almost no waste in the powder coating process. Additionally, an expert can apply as much (or as little) powder as necessary in one application. Rather than allowing the parts to dry between coats, everything is done at once, which saves money and time.

2nd Benefit of Powder Coating---- Low Cost

Along with the money you’ll save by eliminating extra steps, powder coating is cost-efficient in a few other ways. The powder is less costly than paint, and it takes up less space when stored.

3rd Benefit of Powder Coating----Durability

As far as the powder is concerned, powder coating is more durable than most other options. When it cures, the powder will form chemical bonds in the process and creating a flexible, durable finish. Powder coated parts are highly resistant to corrosion, flaking, and scratching.

4th Benefit of Powder Coating ---- Variety

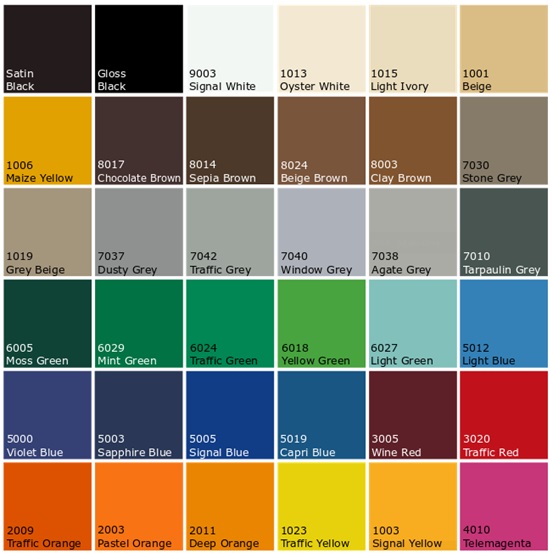

While powder coating has a few common finishes and colors, one of the biggest benefits of the method is the potential for customization. Powder manufacturers will create unique blends to match any color, texture, and finish. The products can be made per different color card as below show.

5th Benefit of Powder Coating ----Environmental Safety

Because the powder is free of toxic chemicals and solvents, it’s regarded as safe for usage and disposal. The processes release no harmful chemicals into the air, and they produce less waste. However, expert painters know to avoid inhaling the powder and to wear safety gear that minimizes skin contact.

6th Benefit of Powder Coating ----Quality

Because the powder melts and reforms as a solid, it creates a smooth surface without drips or runs. Therefore, there’s no need to sand or refinish if mistakes are made.

7th Benefit of Powder Coating ---- Maintenance

Powder coating is easy to maintain; no special solvents or cleaners are required. Because these coatings are so resistant to corrosion and damage, there’s no concern over rust and other cleaning-related damage. In most applications, an occasional wipe with soapy water is enough to keep parts clean and useful for years into the future.

With the proper equipment, powder coating decreases finishing time, improves quality, and leaves users with a variety of finish options.

What products can use powder coating?

Thousands of different parts and products use powder coating:

1. Appliances Hardware

Appliance companies use powder coating applications on stoves, refrigerators, washers, dryers, dishwashers, air conditioners, water heaters, microwave ovens, and many other areas. Metal parts on washer and dryers are now powder coated instead of using porcelain enamel.

2. Automotive Hardware

Powder coating is used often in the automotive industry. Hubcaps, bumpers, wheels, decorative trim, door handles, truck beds, accent parts, filters, radiators, and various engine parts.

Auto bodies are starting to include a clear powder coat to help increase protection. Volvo, Jaguar, Chrysler, Ford, GM and VW all use powder coating in different aspects of their automobile creation.

3. Commercial Buildings Products

Powder coating is used in the architecture and building markets. Framing, aluminum extrusions for doors and windows, modular furniture, and interior railing use powder coating.

4. Highway Products

Many highway projects use powder coating as well – guardrails, light poles, fencing, posts, and signs.

5. Normal Daily Products

These products include antennas, lighting fixtures, and electrical elements. Farm equipment and tractors use powder coating. Fitness industries use powder coating on golf cards, golf clubs, ski poles, bicycles, snowmobiles, and other different types of exercise equipment.

Powder coating VS Painting

Painting is the traditional process of applying liquid paint to a metal product for finishing. Most sheet metal fabrication processes will use a spray, pump, or pressurized vessel to deliver the wet paint evenly.

Powder coating provides better performance than wet paint. Below are the 7 benefits of powder coating process when we compare Powder coasting VS Painting

1. COST EFFICIENCY

When economic factors are taken into consideration, the main benefit of the powder-coating process is its efficiency. Powder coating has a general transfer efficiency of 60–70%. And Paint has a transfer efficiency of only 30-35%.

2. MORE SAFE ENVIRONMENT

Compared to spray painting, powder coating is a safer process because the active product — polymer powder — is inert and therefore free of toxins. Paint, by contrast, usually has toxic solvents and volatile organic compounds that can be harmful if inhaled.

3. ENVIRONMENTAL FRIENDLINESS

Since there are no toxins or volatile organic compounds found in powder polymers, unused portions do not emit greenhouse gases. Since the majority of a given powder supply ultimately does get put to use, the option is also easy on landfills. To the contrary, each application of spray paint sends toxins into the atmosphere.

4. MECHANICAL CONVENIENCE

Powder finish has a thickness that is stronger and more difficult to crack or peel. Powder finishes are also more bendable, and this makes powder a better option when we need to move parts.

5. PRODUCTIVITY

Powder coats also help speed along the production process thanks to the short time it takes for powder polymers to cure on a surface. Unlike paint, which may need days to fully dry, the powder will fully cure in 20 minutes or less.

6. COLOR ACCESSIBILITY

When it comes to color-matching, wet paints offer the advantage of showing their final, dry-state colors right from the start. This makes it easier to mix and match paints with greater accuracy and achieve hues that are slightly off the basic color scale. Any place you turn to for wet paint, the supplier can easily mix primary and secondary colors to achieve the exact match of a required hue.

By contrast, the blending of powder colors involves a specialized production, in which the hue of a given color relies on the polymers that are broken down to form the powder. Consequently, the hue of a mixed color can be difficult to determine in advance.

7. RELIABILITY

If left exposed to water or moisture, metal can develop rust in spots. In the most concentrated of rust-afflicted areas, holes can form within the metal surface. A solid coat of paint or powder prevents these corrosive effects from taking root on the surfaces of metal, but only as long as the finish remains intact. Since powder finishes are stronger and more durable than paint coats, powder will generally guarantee superior, longer-lasting protection to the surfaces of metal-bodied products.

The colors of powder coatings also last longer thanks to the retentive properties of polymers, which mostly resist the chalking effects of moisture, heat and UV rays. Paints, by contrast, slowly undergo a breakdown in resins and fade from prolonged exposure to sunlight, moisture and heat.