What is CNC Milling Machine?

What is CNC Milling Machine?

Milling is a process of removing material by using rotary cutters mounted into a machine. CNC (computer numerical control) milling is a computerized version of milling where machine operators program a machine to carry out the milling operations automatically. CNC milling covers a broad spectrum of operations utilized by several industries. We're going to talk about the types of CNC milling machines.

Types of CNC Milling Machine

1. Vertical Milling Machine

Vertical milling operations have the tooling rotation running vertically (in the direction of gravity). A simple vertical CNC machine will have three axes where the tooling moves vertically; the table moves from the front to the back of the machine, as well as from side to side. These machines are common in many machine shops because they are cost-effective, simple to program, but still offer diverse capabilities.

2. Horizontal Milling Machine

Horizontal milling machines have the same primary function as vertical machines— removing material from a component; however, in a horizontal milling machine, the tooling spins horizontally. The two different machines can use the same type of tooling as well. Horizontal milling machines are often more expensive but are better suited for production machining.

Horizontal milling machines will often have a fourth axis for rotation. The table can rotate to allow the milling head to access other sides of the part. For production (producing many of the same parts) this machine also has a pallet changer. The machine has two working areas. One where the components are being machined and another where an operator can safely work on the next set of components. The advantage is the optimization of cutting time. Without the pallet changer, the machine sits idle while an operator is switching our components or changing machine setups.

3. Multi-Axis Milling Machine

Each additional axis represents an additional type of movement. Going beyond three-axis machines greatly expands the capability of a CNC machine.

3-Axis milling machine

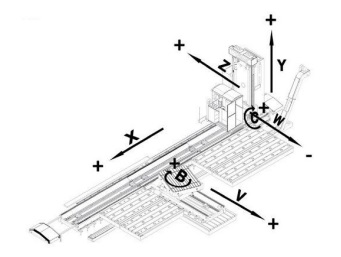

3-Axis Machining is the Most Widely Used Technique. Evolved from the practice of rotary filling, 3 axis machining is an average manual milling technique cutting parts on three axes; the X, Y, and Z axes. Invented in the 1800s, the vertical 3 axis CNC milling machine has come a long way in its capabilities. While many machines have a moving bed, the 3 axis milling centers are still while the cutter itself operates instead. 3 axis models are multifunctional, accurate machines designed for:

Automatic/Interactive Operation

Milling Slots

Drilling Holes

Cutting Sharp Edges

3-axis milling is capable of creating the same products as 4 axis and 5 axis machines, but the 3 axis machines cannot deliver the same level of detail or efficiency as its predecessors. 3 axis can cut individual features during operations, but it cannot match the work of a 5 axis in quality or profitability.

4-Axis milling machine

Similar to the 3 Axis CNC vertical milling machine, 4 axis micro-milling machines are vertically operated and built to function in a timely fashion. They are user-friendly with manual and computer lead operations. Built for detail work and accuracy, 4 axis is a step away from the high quality, precise engravings, drillings, and millings of a 5 axis machine. Despite its shortcomings, the 4 axis CNC machine can be used for different purposes, including:

Industry

Technology Research

Teaching

Hobby Prototype Building

Advertising Design

Creating Art

Medical Equipment Creation

With the ability to operate on wood, foam, composite board, aluminum alloy, and even PCB, 4 axis is a multi-use CNC tool functioning at a slightly higher competency than the 3 axis.

5-Axis milling machine

The best CNC milling machines available today, 5 axis milling is a fast working, precise, micromachining powerhouse. Owens Industries specializes in 5 axis machining because of its superior functions compared to the 3 axis and 4 axis CNC Machines. A 21st-century marvel, a 5 axis CNC machine is capable of impeccable product and parts creation. This extremely fast milling machine, unlike the 3 axis and 4 axis, has the capabilities to efficiently and impressively produce:

Artificial Bones

Aerospace Products

Titanium Creations – For Both Practical and Artistic Purposes

Oil and Gas Machine Parts

Car Moulds

Medical Technology

Architectural Door Frames

Military Grade Products