CNC lathe axis in different types

Generally speaking, lathes are divided into different types such as 2-axis cnc, 3-axis cnc, 4-axis cnc, and 5-axis cnc. Choose the right type of lathe according to the product to be processed.

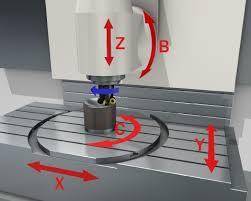

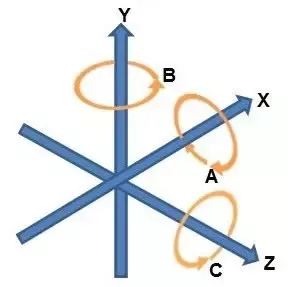

XYZ is a linear axis, where Z is aligned with the main axis of the machine.

ABC is a rotation axis that rotates around XYZ, respectively.

UVW are parallel linear axes along XYZ, respectively.

2 axis CNC lathe

With only 2-axis XZ, standard lathes are very versatile. You can rotate parts inside and outside.

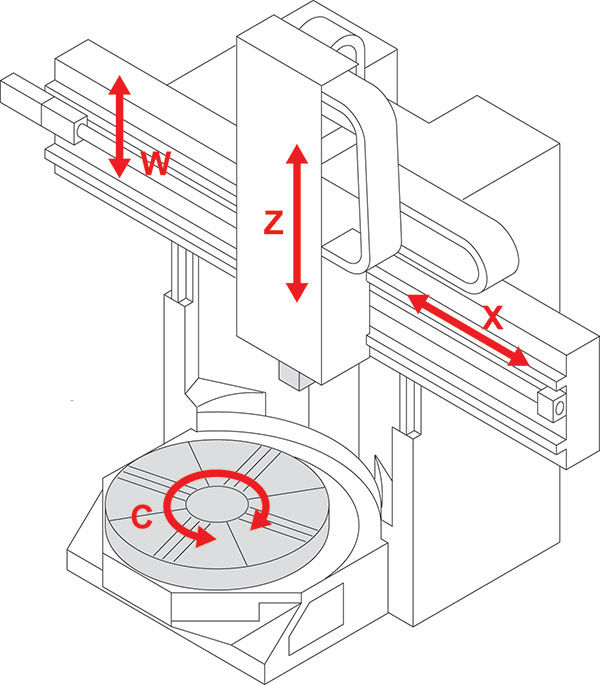

3 axis CNC lathe

The third axis (Y) is perpendicular to X and Z, and the curve can be processed. The Y axis is driven by a ball screw actuator and slides on a linear guide or a box guide.

Get movement by moving the tool in other ways. Some machines have multiple tool positions on multiple tool holders, and there are power tool slots on the turret, driven by motors. The turret is installed on a carriage or cross rail.

Others may have special milling cutter drivers installed on the turret surface. This automatic tool changer requires a larger motor and can hold up to 30 tools. There are also some Y-axis guides installed on inclined beds.

Other manufacturers have installed independent milling heads with tool change. Also, others have installed independent milling heads with tool change function.

4 axis CNC lathe

In order for the live tool to be effective, the workpiece must be oriented accurately. This is done through the main shaft or rotating the C axis.

When the spindle stops rotating, the micro-servo motor in the tool mounted on the turret functions, thereby turning the lathe into a traditional milling machine. Using a servo motor to maintain position will allow positioning and contour movement. By using the C axis for simultaneous X-Y-Z movement, contour cutting can be performed in this way.

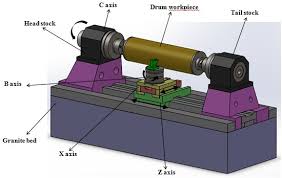

5 axis CNC lathe

The 5th axis is usually A-axis or B-axis, so the machine tool has XYZAC or XYZBC tool path.

The B-axis function distinguishes the 5-axis machine tool from the previous 4 machine tools. The axis rotates around the Y axis, which can be cut at a compound angle. The 5-axis CNC machine supports all ranges of milling and turning, so all milling and turning operations can be performed in one setting.