The difference between cold heading and cold extrusion

Cold heading and cold extrusion are basically deformation processing under the same conditions, but the operation methods are different. Cold forging belongs to the forging deformation of smaller workpieces and is often used in the fastener industry. The cold extrusion is the extrusion deformation of larger workpieces and has a wide range of uses.

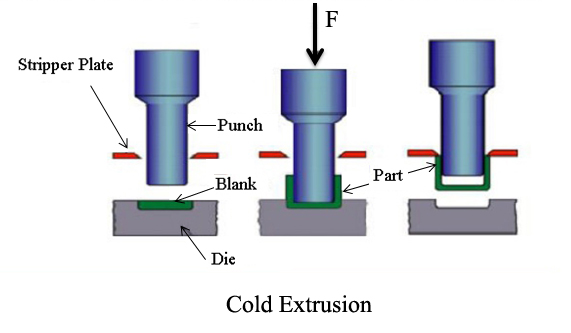

1. What is cold extrusion, the definition of cold extrusion

Cold extrusion is a processing method in which the metal blank is placed in a cold extrusion die cavity, and at room temperature, pressure is applied to the blank through a punch fixed on the press to cause the metal blank to undergo plastic deformation. Obviously, cold extrusion Press processing relies on molds to control the flow of metal, and relies on a large amount of metal volume transfer to form parts.

If the blank is extruded without heating, it is called cold extrusion. Cold extrusion is one of the machining processes of non-chip and less-chip parts, so it is an advanced process method in plastic processing of gold chips. If the blank is heated to a temperature below the recrystallization temperature for extrusion, it is called warm extrusion. Warm extrusion still has the advantage of less chips and no chips.

Cold extrusion technology is a high-precision, high-efficiency, high-quality and low-consumption advanced production technology, which is mostly used in the large-scale production of small and medium forgings. Compared with hot forging and warm forging processes, it can save 30%-50% of materials, save energy of 40%-80%, and can improve the quality of forgings and improve the working environment.

At present, cold extrusion technology has been widely used in industrial sectors such as fasteners, machinery, instrumentation, electrical appliances, light industry, aerospace, shipbuilding, and military industry. It has become an indispensable and important processing method in metal plastic volume forming technology. one. With the advancement of science and technology and the continuous improvement of product technical requirements in industries such as automobiles, motorcycles, and household appliances, cold extrusion production technology has gradually become the development direction of refined production of small and medium forgings.

Cold extrusion is also divided into forward extrusion, reverse extrusion, compound extrusion, radial extrusion and so on.

2. What is cold heading, the definition of cold heading

The cold heading process is one of the few new processes for non-cutting metal pressure machining. It is a processing method that uses the plastic deformation generated by the metal under the action of external force, and with the help of the mold, the metal volume is redistributed and transferred to form the required parts or blanks. The cold heading process is most suitable for the production of standard fasteners such as bolts, screws, nuts, rivets, and pins. The equipment commonly used in the cold heading process is a dedicated cold heading machine. If the production volume is not too large, crank press or friction press can also be used instead.

Because of its high productivity, good product quality, and greatly reduce material consumption, lower production costs, and improve working conditions, cold heading technology is more and more widely used in mechanical manufacturing, especially the production of standard fasteners. The most representative products produced by the multi-station cold heading machine are bolts, screws and nuts.

3. Are cold heading and cold extrusion the same thing?

Cold forging and cold extrusion are basically deformation processing under the same conditions, but they are different in operation. Cold forging belongs to the forging deformation of smaller workpieces and is often used in the fastener industry. Cold extrusion is the extrusion deformation of larger workpieces and has a wide range of uses; cold heading is equivalent to a branch of cold extrusion. Simply put, in the process of making bolts, the hexagonal head forming is cold heading, and the rod is reduced. The diameter is cold extrusion (positive extrusion). Non-trimmed hexagonal flange bolts (multi-station forming) have both cold heading and cold extrusion. The front side shaping of the hexagonal nut is only cold heading, and the latter process is cold extrusion (positive and negative extrusion).