6 Milling Design Tips to Save Milling Cost

In the design of non-standard machinery parts, it is often seen that a large number of milling parts are used in some machinery and equipment, ranging from dozens to hundreds (the sample stage is particularly prominent). In such mechanical equipment, the cost of individual parts largely reflects the price of the entire machine. Therefore, when designing parts, engineers should master some experience skills to reduce the cost of parts. In this article, I will share 6 commonly used milling design tips with you.

In the design of milling parts, the processing difficulty and precision requirements of the parts will cause great changes in the processing of the parts. Therefore, it is very important to master the design knowledge of milling parts. Simply put, it can be considered from the following three aspects.

.Tools involved in parts processing;

.The difficulty of parts processing;

.Processing equipment (existing or required) involved in parts processing.

Let's take a look at the embodiment of these three milling design perspectives, namely milling design tips.

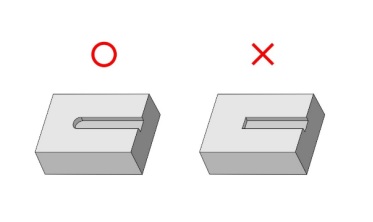

1. In groove machining, the tool (end mill) is cylindrical, and the machining end is a rounded corner with a radius R. As shown in the figure, if the end of the groove is a corner, the processing cost will become higher.

As shown in the figure below, the tool (end mill) is cylindrical, so corners cannot be cut. In order to cut corners, special processing such as electrical discharge machining is required, which virtually increases the cost.

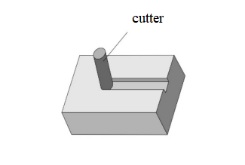

2. If there is no problem in the milling design, this kind of pocket shape is best to open the end face. In the case of a closed end face, the tool must be punched first (that is, the tool must be processed down to the size surface and then moved), and the work efficiency will be lower.

Similarly, in the case of processing wide grooves, a larger R will produce higher processing efficiency and lower processing costs. This is because you can use large diameter tools and reduce the number of reciprocating movements. Therefore, if there is no problem with the milling design, it is best to specify as large R as possible in the diagram.

3. For some parts, it is necessary to machine from the rough surface (or rough surface) to the target size. If the thickness of the material (blank) exceeds the target thickness, the processing cost will increase.

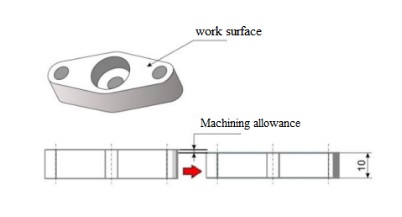

Therefore, the thickness of the plate should be set by considering the "machining allowance", and a material with a thickness close to the target size should be selected. Machining allowance (or allowance) is the cutting allowance before reaching the target size. For example, as shown in the figure below, when cutting from a 12mm material with a target size of 10mm, the machining allowance is 2mm.

Extended knowledge: "Machining allowance" is different from "finishing allowance". Rough machining is performed from the material before machining, and the remaining amount in the state before finishing is the finishing allowance. Although it depends on the processing method, the finishing allowance is usually 0.1mm to 0.5mm.

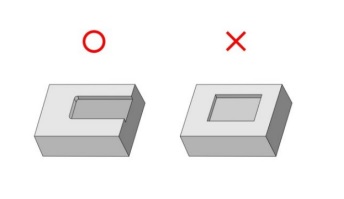

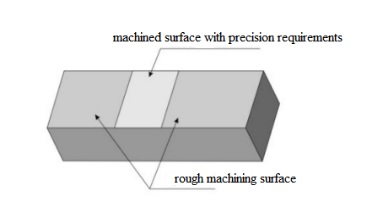

4. The width of the required size and shape accuracy should be as narrow as possible within the working range of the part. By making it narrower, the cutting cost can be reduced because it can be cut once with a milling cutter. On the other hand, if there is an increase in the width requiring accuracy, the milling cutter must reciprocate multiple times, thus increasing the processing cost.

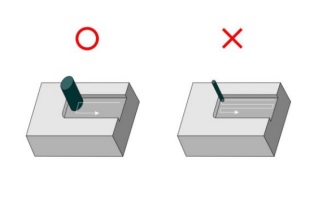

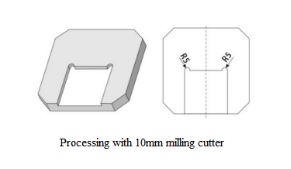

5. In the case of the shape shown below, if there is no milling design problem, select a suitable tool. With suitable tools, the need for tool replacement can be eliminated and the labor hours of workers can be reduced, thereby reducing costs.

6. The dimensional tolerance depends on the size of the part, but considering the machine specifications, it should be kept within ±0.02. This is a rule of thumb, but if higher precision is required, the processing cost will be very high.

For example, in the case of ±0.1mm, it can be measured with a vernier caliper, but ±0.02 is difficult to measure with a vernier caliper. The higher the accuracy, the higher the processing cost. Therefore, when drawing a drawing, the appropriate precision should be selected to avoid excessive precision.